Dear Guest,

Please register or login. Content don't create itself!

Thank you

-

Lyrebird Cycles

Lyrebird Cycles

After I finished my stint in the Navy, where I’d trained as an aeronautical engineer, I went sideways into biological sciences and got as far as starting a PhD scholarship before figuring out that academia wasn’t for me. I then moved into winemaking where I’ve worked for most of the last thirty years with interludes working as a brewer, a process engineer in the food industry and running a business where I designed and built bespoke audio electronics. Within any of these fields I rapidly became the troubleshooter / problem solver, trading on my ability to absorb a lot of information quickly and apply bits of it to fields where it didn’t formerly belong. Basically, I have a brain made of flypaper: all kinds of random shit sticks to it.

While I was working as premium winemaker at the now sadly defunct Seppelt winery in Great Western, VIC in 2008-09, I spent a lot of time on my old steel road bike in the Grampians range, particularly the Mt William Climb, http://theclimbingcyclist.com/climbs/mt-william/ which is a beautiful road but a pretty rough surface. One day whilst dodging holes and cracks I found myself pondering the question of what made “ride quality” and the thought struck me that it was similar to a signal to noise ratio problem in acoustics, the signal being the responsiveness and road feel of the frame, the noise being ride harshness and road buzz. My original theory was that these things resulted from different vibrational modes of the bike, so I set about designing a way of encouraging the “signal” modes and discouraging the “noise” modes by selectively modifying the wall thickness of a titanium frame.

I proposed this idea to Darren Baum on a very memorable day http://www.velocipedesalon.com/forum...l%23post369554 in 2009 and although Darren made a very generous offer which would have helped with the development, I could not afford to take him up on it at the time. A little later I bought a cheap US made straight gauge Ti bike frame, a power file and an ultrasonic thickness gauge and did it myself. To provide something of a control, I rode the bike in its unmodified condition for long enough to become familiar with its character, the disassembled it, modified the frame and reassembled it exactly as it had been, including tyre pressures. The process took me around a week and I expected any effect to be subtle at best. It wasn’t, the bike was very different in feel.

I took this as a demonstration that the way the frame itself flexes / vibrates is important for road feel and that doesn’t seem like anything remarkable, though it’s news to some. Much of the process involved in the change was similar to externally butting the tubing so it was possible that this was the source of the effect I was seeing. BTW that’s also why I haven’t explained much about modal vibration theory, since it’s A: easily Googleable and B: no longer the basis for what I am doing. I became convinced that that the way the frame itself flexes / vibrates isn’t the entire answer to the ride quality riddle and may only be a small part of the answer.

At some time during this my Father in Law, who makes and repairs stringed instruments, pointed me in the direction of the types of woods luthiers use, known in the trade as tonewoods, and the increasing interest in the use of Australian tonewoods. I started investigating the acoustic and mechanical properties of these woods and became convinced that they would be able to be incorporated into the structure of a bicycle. I put this idea together with some of the materials research I’d done for the audio business to come up with “The Tonewood Project”.* http://www.velocipedesalon.com/forum...ect-31007.html

The first bike I built was in 2012, by which stage I’d been playing with these ideas for around three years, including a lot of time working out ways of fabricating the tubes and incorporating fibre composites. This first bike incorporated a lot of stainless steel because at first I wasn’t sure that the tonewood composite construction would be durable enough. After a year or so of trying to batter it to death with no success I became more confident and the next prototype had stainless chainstays and tonewood composite everything else.

By this stage I had enlisted VSalonista Rich the Roadie as beta tester - basically as a reality check because it’s awfully easy to become prey to confirmation bias http://www.sciencedaily.com/terms/confirmation_bias.htm when you’ve been working on something for this long. I asked Rich because he had a lot of experience with some excellent bikes and while he was interested in what I was doing he wasn’t convinced, so he would truly be a fresh pair of eyes. Rich has written about his impressions here: http://www.velocipedesalon.com/forum...s-39471.htmlin short, his response to the bike confirmed that at the very least if I was imagining this stuff it was a collective hallucination.

*The information in this post is now largely superseded, my techniques have been refined over the years since it was posted.

Mark Kelly

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

Meanwhile I dreamt up the name Lyrebird Cycles: The Lyrebird (Menura novaehollandiae) represents an extraordinary fit with what I’m doing. It is native to the montane forests of south eastern Australia which are both part of the inspiration for the bikes and the source of some of the tonewoods I use, plus it’s subtly beautiful and renowned for the musicality and complexity of its song:

I also had an idea for the script I wanted to use, taken from the lettering used on veteran’s honour boards around the country: the particular example I used was from Prahran, where one of the names on the board is “Monash, John Sir”:

Monash, John Sir.jpg

Sir John Monash was the commander in chief of Australian forces in WW1 and yet there he is on the board with the ordinary soldiers.

On a personal note: I didn’t realise until later that he was the signatory on the citation for my grandfather’s medals for bravery under fire at Albert (near Pozieres) in 1916.

Armed with an idea of what I wanted but not the talent to make it happen I asked for help on VSalon to get a font designed on this script and perhaps develop a logo. The depth of talent in this place is extraordinary: member Chooey (Melvin Choo) came on board and has done some extraordinary work.

Initially we spent an afternoon talking about what I wanted to achieve and where all this had come from, with me typically wandering off on long tangents about such things as the association of lyrebird habitat with the myrtle beech and the importance of the myrtle beech to the history of the concept of Gondwana whilst Melvin asked lots of pertinent questions about the relevance of these things to the project at hand.

Melvin then got to work on some concept sketches that embodied the more relevant ideas:

Scene 1 Lyrebird.jpg

It's worth clicking in these two images to see the detail in Melvin's work.

These are just some of the pages and pages of sketches he did: he put a huge amount of work into developing these ideas and liaising with me on how they fitted with what I wanted to do. Some things were very fluid: myrtle leaves went in and out of the design several times before finally being rejected. Some ideas came in and simply stuck, such as having the lyrebird “in song” and having five linear feathers to evoke the musical stave:

Scene 2 Lyrebird.jpg

The final design is wonderful:

Logo Black Gold.jpg

It balances elegance and complexity, it is at once laden with signifiers yet able to be taken as an entity by itself. I couldn’t be happier.

Mark Kelly

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

Your story is compelling and I LOVE the brand logo.

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

Josh

Thanks for your encouragement. This wouldn't have worked out half as well without VSalon.

Speaking from wine industry experience, it's normally hard to find a good designer and it's pot luck whether they actually understand what you are on about. Chooey is enormously talented and has shown great insight into how my made ideas could work.

Mark Kelly

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

Acoustics part one:

As I’ve mentioned before my Father in Law is a luthier, he makes and repairs stringed instruments; guitars and banjos (we try to forgive him for the latter). He pointed me in the direction of the woods luthiers use, known in the trade as tonewoods. These are woods which are believed to have properties which allow the instrument makers to “voice” their creations by manipulating the effect they have on tone colour. This appears to involve the material preferentially damping frequency ranges corresponding to certain overtones whilst allowing full energy recovery at primary vibration modes: too much damping at these modes would mute the “voice” of the instrument.

There is currently a lot of interest and research into Australian tonewoods: there are about 2000 species of hardwoods that grow here (and mostly nowhere else) and they include the tallest, largest and possibly the hardest hardwoods known. At the same time Australian Eucalyptus species are the first choice for feedstock in fine paper production worldwide: that may seem like a non-sequitur but it’s actually relevant, more on this later.

So I started looking at the properties of these tonewoods, focusing on the velocities of sound (yes, that’s a plural, there are several of them) and acoustic impedances. The acoustic impedance of a material is given by

z = ρ v,

eg it is the product of the density and the velocity of sound in the material.

For some years I have been involved in audio design as a side line, I’m primarily known for producing very high performance motor drives for turntables but I also did a lot of design work on other aspects of audio design. This included research on the way that motor vibrations propagate through the materials used in the turntable base structure and a large part of this work looked at the way that vibrations cross the interface between different materials, which is largely governed by the difference in acoustic impedance: the coefficient of reflection at a boundary is the proportion of energy which fails to pass across the boundary and is given by

R = ((Z1 - Z2) / (Z1 + Z2))^2

It therefore becomes important to minimize the differences between acoustic impedances of the parts of a structure to create an acoustically coupled whole. If two materials with very different acoustic impedances are to be coupled one method is to interpolate materials with intermediate impedances: because the reflection coefficient is governed by a square law, the net reflection is effectively reduced. Anisotropic materials like woods and fibre composites naturally have different acoustic impedances in different directions and this can be manipulated to achieve improved coupling by orienting the materials correctly.

The scale at which this is relevant is governed by the wavelength of the vibrations which is in turn a function of the frequency and the velocity of sound in the material. The velocities of sound through a material are a function of the stiffness and density: according to the Newton – Laplace equation

c= ((δp/δρ)s)^(1/2)

eg the velocity of sound is the square root of the stiffness to weight ratio. This is obviously a useful metric for materials to be used in making lightweight highly stressed structures like guitars or bicycles. It turns out that the extensional velocities in some of these woods are equal to those of titanium and aluminium alloys.

It seemed to me that these were good candidates for an experiment on the effect of acoustic materials on ride quality, so I started looking at how to incorporate all this into a bicycle frame. I knew from the outset that I would need to incorporate fibre composites to achieve the properties I wanted, so I set out to look at the acoustic properties of the various available fibre composites. One key decision here was to get hold of some boron fibre composite; Gary Klein’s original research way back in the 80s indicated that it had interesting acoustic properties. I spent quite a bit of time looking at ways of constructing tonewood /composite hybrid structures and formed some theories about how the interactions between the materials affect the propagation of vibrations through them.

A further explication of this will require another post with lots more equations.

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

Read every word. This is fascinating.

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

I saw Rich out on his Lyrebird this morning. I went to some effort to see what brand it was as it just looked like a very nice bike. And then i noticed the wood.

What do you use for a fork? Is that wooden or some enve thing?

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

It was great to be back on it, too - I forgot how damn good a bike it is.

The fork is a painted carbon number that I had spare from an old build - I think it’s a Chinese brand, but it looks to be almost exactly the same as the one Curve use and sell. I painted it along with the stem to match.

Where did you see me? I assume you were in one of the groups on the way up the beaches?

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

We were behind you from Collaroy, but i didnít realize it was you until just before we turned off to Akuna Bay. Saw the frame, then the gloves and the shoes finally sold it. That was a lot of red lights!

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

Originally Posted by

Colinmclelland

That was a lot of red lights!

Man, I haven't hit that many on one ride in *months*! Hope you had a good ride despite the rain.

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

Originally Posted by

RichTheRoadie

Loving seeing your process afresh, Mark.

I just love seeing the process!

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

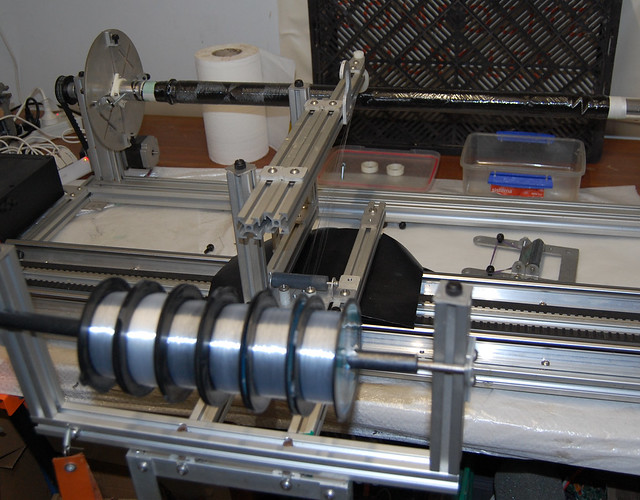

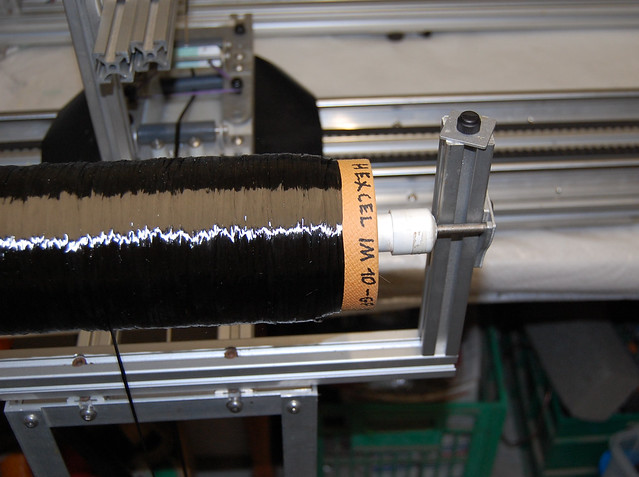

Boron

The strange looking semi-metallic sheen is due to a strange semi-metal: boron.

From bottom to top: base tube, boron laterals, shrinkwrapped ready for oven.

Boron is incredibly strong in compression because it is far more resistant to buckling than carbon. This same property means it will not conform to an uneven surface, thus explaining the fuss earlier about making sure everything is flat and even.

Oh, the peg stops the tube rolling, nothing more.

Mark Kelly

-

-

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

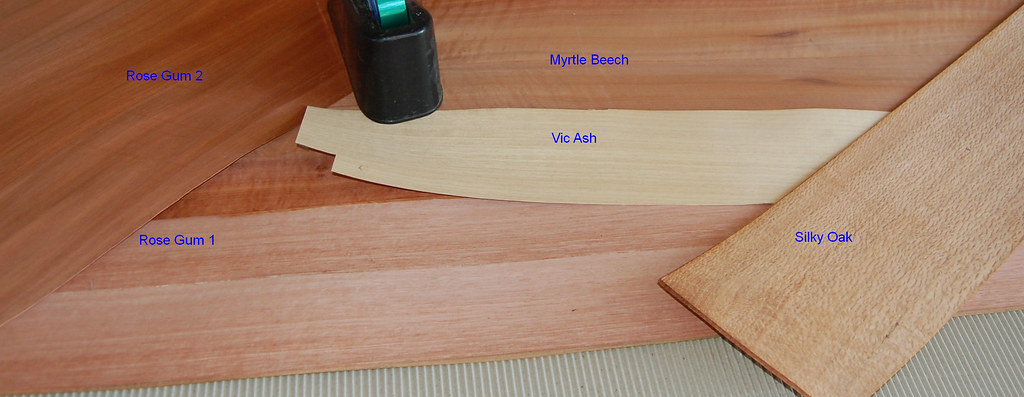

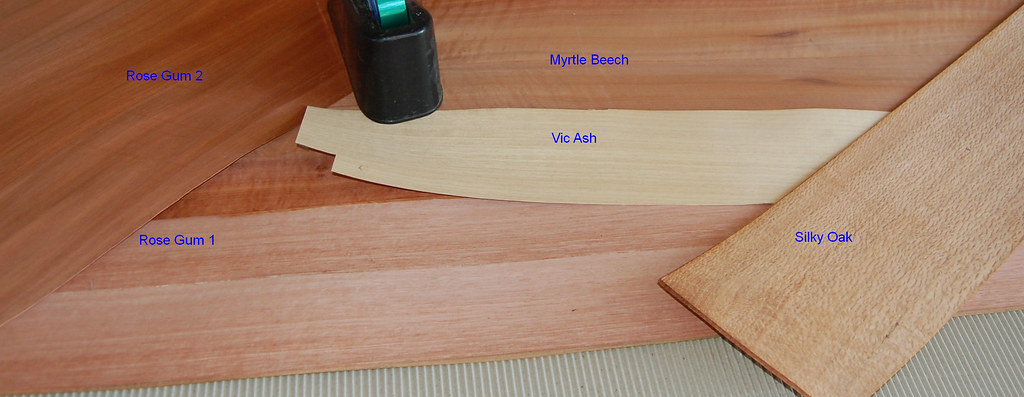

Selection of leaves for outer layers:

Leaves

Mark Kelly

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

Originally Posted by

Mark Kelly

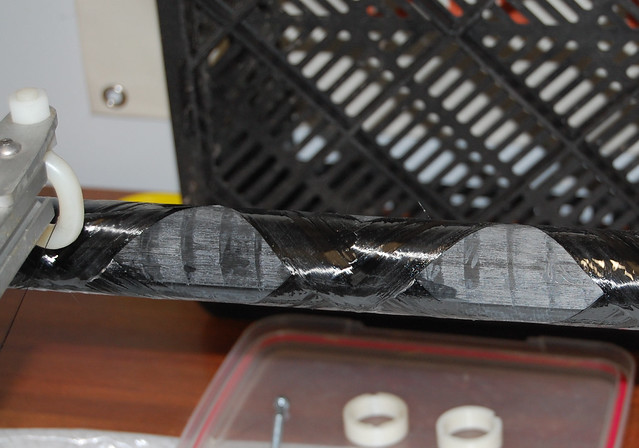

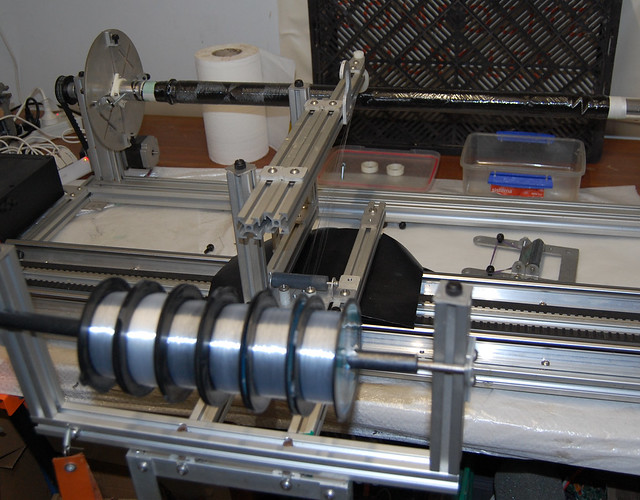

Since the compression is basically radial, I changed to using 6 reels of 0.3mm fishing line and tensioning by hand (you can't see the hand because it's taking the pic). Note how the bound part (to the left) makes the winding pattern more evident.

Binding

Binding

This leaves a carbon surface and tiny epoxy ridges which are easily knocked off by scraping back with a hard edge. I then grind down by about 10% of the laminar thickness and end up with a very even flat surface onto which to bond the next layer.

Re-reading this thread, itís fair to say I have zero understanding of what you do after you have wrapped the tube with fishing line....

How do you grind anything down without just removing the freshly wound fishing line?

Colin Mclelland

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

Colin

Sorry for the slow reply. I have found a better method of binding the tubes so I don't need the fishing line any more. In any case the fishing line was stripped away once the epoxy cured.

Mark Kelly

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

Joints_1

In the home stretch, just finishing off the joint binding.

Something like 82 individual tessellae and over 20 metres of hand laid carbon 12k tow.

Mark Kelly

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

I'll be patient and just wait to see how you do it, but i'll be fascinated to see how you deal with the joins, as I know there isn't an inch of exposed carbon in the finished product.

Mind you, the whole thing has been fascinating. Thanks for posting the process.

Colin Mclelland

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

There’s a fair bit of exposed carbon on mine.

Similar Threads

-

By Boedie in forum Smoked Out

Replies: 30

Last Post: 11-22-2014, 05:45 PM

-

By magnoliacycles in forum Smoked Out

Replies: 25

Last Post: 04-11-2011, 04:57 PM

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Likes:

Likes:

Reply With Quote

Reply With Quote

Bookmarks