Dear Guest,

Please register or login. Content don't create itself!

Thank you

Likes:

0

-

Re: Cycles Noir

Re: Cycles Noir

I'm bit overdue for an update here. Hope everyone hasn't been waiting on the edge of their seats!

The tour is over, which means new bike/product season is in high gear. Manufacturers bring many products out during the tour, then there's Interbike at in the fall. Between these two events are a whole series of PR announcements of new and improved products. Virtually all of these are distinguished as being part of the upcoming mode-year - whether they are immediately available, or not.

This phenomena is one proof (if one is needed) that custom builders are in a different business from the big guys. It's possible that you can tell the build date from the serial number on a custom frame, but custom builders don't have model-years. And, manufacturers don't necessary build a given model-year of a bike during the same calander year. So what's going on here?

Both framebuilding and bicycle manufacturing are businesses. And in some cases, the process of sticking bits together to create the frame, and bicycle, are similar. Apart from scale and 'model year' what justifies my contention that framebuilders and manufacturers are in different businesses?

Let me say that I don't (even for a minute) think that the manufactured product is less than great. At the lower price points, a good framebuilder is pressed to compete with manufacturers on a function points per dollar basis. And at the upper end of the range, riders can purchase a variety of bikes ridden to victory on the pro-tour. Now days, the Pros generally ride the actual bikes sold by their sponsoring manufacturers - so this isn't a fiction or a fairy tail. Combine this with the fact that most riders don't have difficult fitting requirements, and the question can be raised: "Why have custom framebuilders?"

As a business, I think that framebuilders have more in common with the cats who build custom hotrods than the Trek & Spec's of the world. We touch our riders in a way that no manufacturer does - and the stories of the various builders here at Smoked Out is evidence of that.

Framebuilders offer, first and foremost, something unique. Working with a framebuilder, you're nearly guaranteed not to see a matching bike anywhere out on the road. As a rider, you're making a unique statement no manufactured bike with custom paint can offer. Framebuilders have no need for yearly model introductions, because each bike is unique. Framebuilders don't need abstract mechanical benefits (600 gm frames that need added weight to hit the UCI requirements) to set them apart from the field. Instead, they can focus on meeting a riders needs: mechanical, aesthetic, and pyschological. And make no mistake, customers select their framebuilders based on unique needs. Some want a frame from a giant in the field, others want to discover a new up and comer. Some are concerned with classic looks, others want to push the envelope of paint and decoration. Some are looking for a cohesive, even branded, look from their builders - others just want input on color. All these riders insist on performance and fit, that's a given. But there are so many ways to achieve these ends - each similar to and different from many other bikes - but unique to the rider in question.

Every framebuilder can't meet every need. Selection of one's builder is a key part of the process, and a good builder helps by noting up front if the fit is questionable. But the product received goes deeper than the actual bike - there is the relationship established with the builder which endures, often beyond the bike itself. And if the means exist, the rider can establish these relationships with more than one builder. Consequently, some riders create a collection of bikes, not because they need to, but because the variety if fun and rewarding.

It's possible to collect modern manufactured bikes. I think that the value in such a collection, however, is more in terms of finding bikes ridden by famous pros, than in enjoying varied solutions to the given problem of how to ride quickly from place A to place B.

Not everyone covets the custom frame/builder. Many prefer to chase the fleeting latest and greatest. For them the annual model-year is a great invention. For those of us looking for something more enduring, however, a custom builder offers a great solution.

And that's what I've been thinking about this morning as I worked to sand the filets on some chain-stay/drop-out joints.

-

Re: Cycles Noir

Re: Cycles Noir

Originally Posted by

CyclesNoir

I'm bit overdue for an update here. Hope everyone hasn't been waiting on the edge of their seats!

<snip>.

right on, bro.

right funkicg on atmo.

stay in the margins and resist the urge to merge.

-

Re: Cycles Noir

Re: Cycles Noir

Originally Posted by

CyclesNoir

I'm bit overdue for an update here. Hope everyone hasn't been waiting on the edge of their seats!

snip

Rick, Great reading!

I've got 2 questions:

Do you consider the framebuilder to be in the drivers seat when it comes to problem solving or do you approach it as a "the customer always gets what he wants" deal? IOW, if a customer asks for a specific solution to a problem would you do it even if it is not the best way or send him somewhere else? This assumes the customer won't be dissuaded.

On your Carbon frames, do you buy tubes or make them yourself?

Cheers

Kevin

-

Re: Cycles Noir

Re: Cycles Noir

Kevin,

Good questions.

So far I'm a bit of a grouch about frame design. I won't do something with which i'm not comfortable, just because the customer wants it so. I'd rather be in charge my odds for keeping him/her happy. That said, I listen to all that is requested, and try to focus on meeting the riders goals/needs, rather than their design requests. Hope that makes sense.

Of course there are always gray areas. Hellanic stays would be one. I don't like the idea of the stay ends joining the thin-walled part of the top-tube. With a heavier gauge tube, I'd consider doing them - but I'd encourage the rider to understand that from my POV, they are a sub-optimal structural solution.

I buy my carbon tubing. It might be fun to play with making my own, but there is the question of time/space. And lots of available tube options (including the option to have Edge build tubes to my spec). Speaking of which, my carbon tube inventory is getting low and I'm going to have to order some more soon.

BTW, I'm impressed by what you're doing.

Rick

-

Re: Cycles Noir

Re: Cycles Noir

Hi Rick,

Thanks, that does make sense and is very close to my point of view as well.

Thanks also for the compliment. Your stuff looks great, too. You should post more pictures I'd like to see more.

Cheers

Kevin

-

Re: Cycles Noir

Re: Cycles Noir

I tend to be photo-challenged. Things get away from me before they're photographed. Others, I can seem to find the right combo of lighting/focus/background to sing. So here's a shot (no art) of a frame that's ready to clean up and paint.

-

Re: Cycles Noir

Re: Cycles Noir

A little filing & a little sanding then off to paint.

Last edited by CyclesNoir; 08-05-2010 at 11:30 PM.

-

Re: Cycles Noir

Re: Cycles Noir

For anyone who is interested, I have some new photos over at www.handmadebikes.blogspot.com .

These show tubes and bits for a CF frame build.

-

Re: Cycles Noir

Re: Cycles Noir

Hi Rick,

Just checked out the carbon parts- looking forward to the build. You should do the play by play here.

Question: Does it ever feel weird or maybe a little wrong when you have to use parts that have so many parts prefabbed? I was thinking of the chainstays with the drops/cable quide alreadt installed.

-

Re: Cycles Noir

Re: Cycles Noir

Hey Chauncey,

Question: Does it ever feel weird or maybe a little wrong when you have to use parts that have so many parts prefabbed? I was thinking of the chainstays with the drops/cable quide alreadt [sic] installed.

Good question. The answer is easy, but it took a while to figure out the explanation.

No, it doesn't feel weird to use prefabbed parts in a CF build.

The explanation has two parts:

1) Virtually all builds use tons of prefabbed parts. That includes Steel, Ti, and Aluminum. CF is hardly the first material where tubing is provided by a manufacturer (therefore pre-fabbed). Fork blades and stays come pre-tapered, and sometimes pre-bent. A steel lugged BB is formed by the manufacturer with each of spigots pre-attached, and has been machined with threads. Very few builders make their own lugs. Metal dropouts are generally purchased as prefab pieces, as are cable stops, and other fittings. While the CF chain-stay is one piece (with a cable stop) and the seat-stay is one piece, that doesn't define CF as just glue-it-together. With CF, building the BB takes more work (ATMO) than with a Steel, Alu or Ti bike. Some of my cable stops are 'shop made' - and as my designs mature, more of them will so be. My internal cable routings are totally 'shop made'. I'm developing new ways to attach fittings that are more satisfactory to me than the pre-fabbed glue and rivet pieces. So, it's easy to look at the rear triangle and think that CF provides a shortcut to building, but that is only based on a limited understanding of total job required to make a CF frame.

2) CF is its own material. Just like any other material, its necessary to understand its properties/behaviors and how various processes affect it. While there are some options for the rear triangle, which can offer differing characteristics, its also possible to modify how the rear triangle behaves. On several bikes I've laminated additional CF onto a prefab stay to make it stiffer. Also, how the chain-stay is connected to the BB and seat-tube will alter its stiffness. So the builder has to think of all these sorts of things and account for them as part of the design.

As you may be able to tell, I'm not a big fan of riveted bits. Don't get me wrong, they work. But the solution is inelegant from my POV. Replaceable plastic inserts (ala some DI2-ready big brand bikes) are also inelegant to me. A molded in stop seems like an advantage to me, for weight, strength, longevity and aesthetics. So that's a piece of pre-fab I'm happy to employ - and don't feel as if it diminishes my efforts as a builder.

Maybe there's a third part of the explanation based on where the state of CF custom building sits in the continuum of time. What to do with a steel build (or Alu or Ti) is pretty well defined and documented in places that are readily available. Standardized bits are available making pieces interchangeable. For CF building, that largely isn't true. Dedaccaia offers it forms of pre-fab head-tubes - although I don't use them and they tend to be particular to a given shaped tube set. They also require integrated headsets which I don't think of as being lifetime (owner not bike) investments. But when I first went to use PMW head-tube rings, there were no instructions, or stock head-tubes in which to fit them. Instead I contacted EDGE and spec'd what I wanted. The same was true of the BB. Mind you, I'm sure that I wasn't the first person to go to EDGE (or the then Reynolds Composites) for head and BB tubes to fit PMW parts. However, they weren't catalog items, and whatever they had produced before was considered proprietary to the builders with which they had worked.

Before that, I used Alu BB's and head-tubes that were designed for Alu frames - which were a bit stout for the job. I'd wet wrap them in carbon to create the BB or head-tube, prior to connecting any tubes or stays.

I may be guilty of crushing an ant here with a sledgehammer, but I hope that its clear that there many aspects of CF building which aren't close to pre-fab.

Rick G.

-

Re: Cycles Noir

Re: Cycles Noir

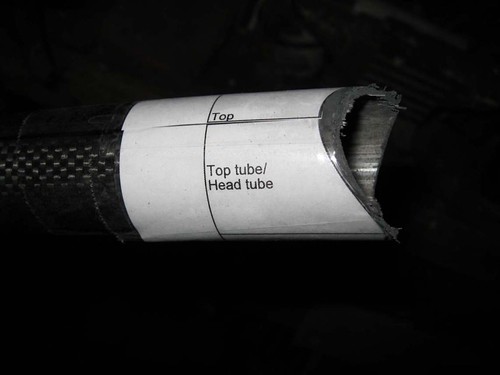

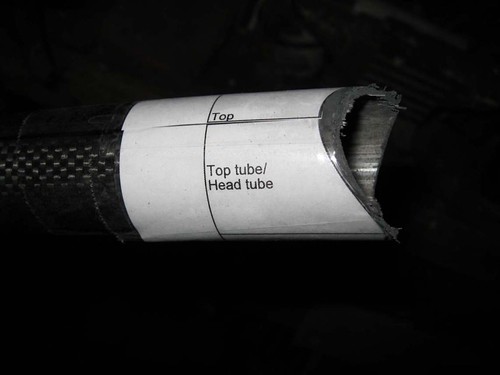

A few pictures here, then next time back at www.handmadebikes.blogspot.com .

To cut the tubes to rough shapes, I use an abrasive carbide blade in a hacksaw frame, here are the blades:

When tubes come in all manner of custom sizes, standard tube blocks aren't likely to fit. That's when a Park bike stand helps:

Even using the abrasive blades (which cut much better [and longer]) than regular toothed blades, it's possible to have individual fibers tear out. Because of the distance between the rough cut and the end of the tube, its hard to do much about this. But, before further cutting I'll put down a layer of medium CA glue inside of the rough cut. This will toughen the end of the tube before final trimming.

And here's the other end of the tube:

All of this step was less than 10 minutes - but there are two more tubes to miter, plus the rear triangle, plus the outer head-tube and BB. Time permitting, I'll have some more pictures to show either Thursday or Sunday.

Apologies that the pix aren't showing properly. Hopefully this will resolve itself by the morning.

Last edited by CyclesNoir; 08-26-2010 at 09:55 PM.

Reason: TT has my pix back on track

-

Re: Cycles Noir

Re: Cycles Noir

For anyone who's interested, there are a couple of new pictures of CF miters over at www.handmadebikes.blogspot.com

-

Re: Cycles Noir

Re: Cycles Noir

Originally Posted by

CyclesNoir

richard that is very cool work being shown there atmo.

-

Re: Cycles Noir

Re: Cycles Noir

e-R,

Thanks.

If you only knew how often I reference your various build pix... To me, they've been a real learning aid.

Most CF builders seem to go after pre-preg, which has its advantages if you can afford the oven. But I thought some folks might like to seem some of the messy details of building a CF frame using some of the more primitive methods.

Ciao,

RG

-

Re: Cycles Noir

Re: Cycles Noir

No laughing, this crowded jumble is my shop:

Meanwhile, the next step of CF frame making is now documented at handmadebikes.blogspot.com

-

Re: Cycles Noir

Re: Cycles Noir

Hi Rick,

your shop looks like mine did before I moved into the new clean one. The only thing stopping me from bringing it back "up" to that standard is my wife.

I like what you're doing with the CF project. There aren't many that share a step by step with this material. You might consider using mold release agent instead of grease to protect the threads of the BB sleeve. It dries so you don't have to worry about touching it and contaminating the outside of the sleeve.

-

Re: Cycles Noir

Re: Cycles Noir

-

Re: Cycles Noir

Re: Cycles Noir

There are a few more pix and an update at HandMadeBikes.Blogspot.Com

Here's a pic that didn't make it into the post:

Last edited by CyclesNoir; 09-02-2010 at 04:47 PM.

-

Re: Cycles Noir

Re: Cycles Noir

Hey Rick, nice to see this stuff for a carbon frame. Thanks! I'd like to know more about how you get it straight with this process. Do you glue it all up in the jig, then put it on the table before hardening? Keep up the good work.

Craig

-

Re: Cycles Noir

Re: Cycles Noir

Hey Craig,

Like your bikes!

With steel frames, I pin, and sometimes tack, tubes in the jig. Then check for straight before brazing up out of the jig. Probably a similar process to yours.

With CF, its sort of similar. I use a toughened epoxy adhesive to bond tubes together in the jig. This is not only strong, but it's much less brittle than the epoxy used to laminate CF. Because of careful alignment checking in the jig, the bonded parts seem to hold their alignment once the adhesive is set. Nonetheless, these get rechecked in the jig post cure.

Then I build up the fillets around the joints. CF doesn't like sharp bends, so a filler is uses to give the structural fabrics a smooth path. It may not be necessary, but everything gets rechecked on the alignment table at this point. things are pretty stable, as long as nothing gets banged around (don't drop the frame on the floor). I suspect the fillets help further stabilize the joints.

Then the joints get wrapped and cured and we have a bike. I do a final alignment check afterwards, but at this point, not much can be done to correct any alignment problems.

And that's basically it.

Thanks for the question.

Rick

Tags for this Thread

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Likes:

Likes:

Reply With Quote

Reply With Quote

Bookmarks