Dear Guest,

Please register or login. Content don't create itself!

Thank you

-

Re: Engin Cycles

Re: Engin Cycles

Originally Posted by

Archibald

OK, that is cool. How is that done?

Picture a very well made bracket that places the front of the lenses on the exact center point of the tripod. Then it has very accurate detentes that stop every 30 degrees and capture all the images and stitch it together. Then repeat with the camera in the up position and down position all while never moving the tripod. The trick is then removing the tripod from the image. It is impossible without some computer aid but all in all it is a real time image. The B&W is what I think makes it super cool.

http://web.me.com/kirkthibault/Site/...lain3JPEG.html

-Drew

Last edited by EnginCycles; 10-13-2010 at 08:53 PM.

-

Re: Engin Cycles

Re: Engin Cycles

So is it related to Quicktime VR? How does one go about doing this given they have the camera equipment? You did a really nice job with it.

-

Re: Engin Cycles

Re: Engin Cycles

Originally Posted by

Craig Ryan

So is it related to Quicktime VR? How does one go about doing this given they have the camera equipment? You did a really nice job with it.

Craig,

I did not take the images and do not own the equipment. I have a friend that has the Canon EOS 5D which is a 21 megapixel camera and he has some serious equipment that goes along with it. The bracket is something like this: Really Right Stuff - Ultimate-Pro Omni-Pivot Package - Kit Configuration Page

He owns this equipment for work and is always interested in doing stuff that allows him to try out some new equipment. The camera is new and he wanted to try some stuff with it. I like the results. He is also WAY more computer literate than myself. I know he had his super mega lap top (MAC if it matters) with him and was viewing it all along the way on his computer. That part was way over my head. The camera part I was cool with but once it went on the computer I was lost.

-Drew

-

Re: Engin Cycles

Re: Engin Cycles

That image is awesome. Very Google Street View.

-

Re: Engin Cycles

Re: Engin Cycles

Originally Posted by

nahtnoj

That image is awesome. Very Google Street View.

Now even better:

krpano.com - HDRPanorama_FULL_HDR_bw

-

Re: Engin Cycles

Re: Engin Cycles

Drew -

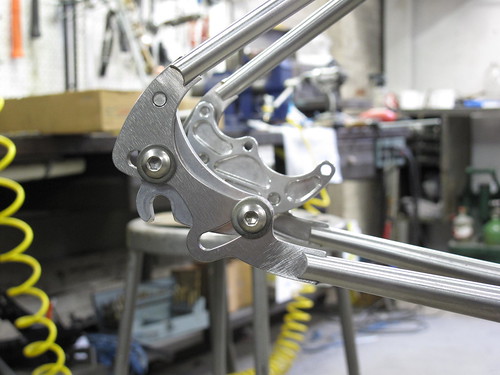

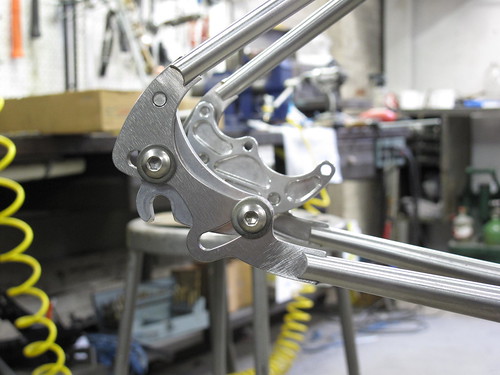

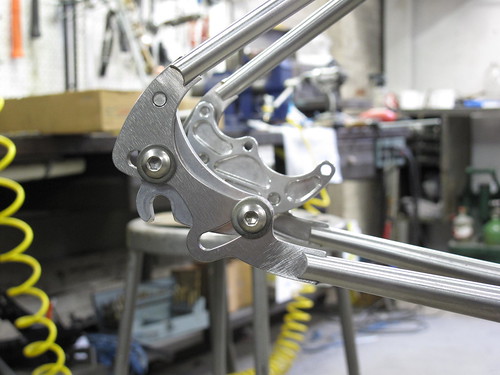

I'm bouncing this thread up to comment on your new drop out - very cool! This thing looks like it will solve a lot of the issues that I've had with other "mechanical" drop outs, and EBBs. I'll be interested to see photos from Austin. This has me thinking about a new frame . . .

Wiki Leaks!!!!!!!!!!! | Engin Cycles

How long has this been in the works? Care to talk about your inspiration? Can you give us a photo in the closed position?

-

Re: Engin Cycles

Re: Engin Cycles

Originally Posted by

billrick

Drew -

I'm bouncing this thread up to comment on your new drop out - very cool! This thing looks like it will solve a lot of the issues that I've had with other "mechanical" drop outs, and EBBs. I'll be interested to see photos from Austin. This has me thinking about a new frame . . .

Wiki Leaks!!!!!!!!!!! | Engin Cycles

How long has this been in the works? Care to talk about your inspiration? Can you give us a photo in the closed position?

The first thing I want to emphasize is I did not totally design the drop out. I had a back and forth with Mark Norstad and after many of my drawings we (mostly Mark) came up with the solution to all the problems. I had one major desire and that was to remove the band-aid from my bikes. The brace required to handle the disc brake forces was something that I tried very hard to make look pleasing but it still bothered me that it was required. So to start I wanted a chain stay mounted drop out. Next was to remove anything that resembled a cantilever design. If rack/fender eyelets are wanted then this drop out works without any compromise. The hurdle we needed to overcome was how long the drop out was from the chain stay mounted brake and the movement for chain tension. That is where Mark nailed it and changed from a sliding motion to a rocking motion and shortened the drop out significantly. The end of the tab in relation to the axle is not any longer than a slider. The pin makes adjusting much easier since you loosen the bolts and the wheel rocks back evenly at all times. There is a ton of surface area that the two plates bear on and this is why it does not require a set screw. The 17-4 material is rock solid and allows the metal to metal contact. I could go on and on but will save it for NAHBS.

The idea was in my head since about this time last year. I started conversations with Mark this summer and I received the first test set about 1 month ago. I actually thought it would happen after NAHBS and did not have my hopes up for getting anything made beforehand. The timing is a nice added bonus. I was not interested in having something that was mine or exclusive. My goal was to have Mark get a product that was a move in the right direction with the continuing popularity of single speed mtb's. I personally will be using this drop out exclusively for all single speed bikes that have disc brakes.

Thanks for the question and I hope I answered everything?

Cheers,

Drew

ps- here is what it looks like once brazed and finished:

Last edited by EnginCycles; 02-05-2011 at 07:49 PM.

Reason: grammar

-

Re: Engin Cycles

Re: Engin Cycles

Awesome. I can forsee these becoming very popular.

-

Re: Engin Cycles

Re: Engin Cycles

Originally Posted by

EnginCycles

Thanks for the question and I hope I answered everything?

Yes, but of course you have inspired more questions! I've bookmarked your webpage and spent a cold rainy Saturday reading your blog. I'm at the point where I'll probably put down a deposit before I bug you with all of my detailed, project-specific questions.

;-)

Thanks, exciting stuff!

-

Re: Engin Cycles

Re: Engin Cycles

I just discovered this fine video on MTBR.

Amazing how much new technology you have in hardtail 29er. And still, I especially like the barrel adjuster on the seatstay. A simple little point, but something I would really use.

-

Re: Engin Cycles

Re: Engin Cycles

Originally Posted by

billrick

I just discovered this fine video on MTBR.

Amazing how much new technology you have in hardtail 29er. And still, I especially like the barrel adjuster on the seatstay. A simple little point, but something I would really use.

Thanks.

Here is a link to a poster I had printed for NAHBS.

SOPWAMTOS posters for sale | Engin Cycles

-Drew

-

Re: Engin Cycles

Re: Engin Cycles

I especially like the barrel adjuster on the seatstay.

Perfect timing! I'm so ripping that off this afternoon... but I'll give you the cred. Thanks Drew!

Chris

-

Re: Engin Cycles

Re: Engin Cycles

I want to hear about these chainstays!

-

Re: Engin Cycles

Re: Engin Cycles

Originally Posted by

cardinal

I want to hear about these chainstays!

Matt,

Sorry, I have been busy but did mean to post about this. Let's see if I can explain this and not make it sound like a bunch of marketing hype.

It is a known fact that a round chainstay is stiffer than an oval stay (maybe not a needed amount but stiffer nonetheless). Now, stiffer is not always better, but in this scenario it's hard to dispute that a round chainstay is stiffer and better than an oval stay (even though the oval chainstay has some incredible advantages when it comes to tire/chainring clearance). I have always been kind of obsessed with the location of bends on rear stays and have spent a good amount of time, money and effort trying to get the ability to bend oval stays. I really wanted to control the locations relevant to different drop outs and stay lengths. Next is the whole large tire trend with MTB's and how difficult it can be to achieve. The ability to control the tire bend would be a very nice feature. I then considered constant diameter stays but just can not deal with the aesthetics of the hooded drop outs for my bikes. Next idea was to stop reverse engineering and start from scratch.

I admit I really prefer keeping my suppliers to a minimum so I don't need to order from lots of people and pay freight all the time. I really like Lon from Nova but rarely order from them. This project seemed like a good opportunity to give Lon a call. He has the connections to get things made and rather quickly. We spoke at NAHBS and had a draft made soon thereafter. The stay I wanted would maintain as much constant 7/8" diameter as possible and still taper down to a 15mm tip (not 12.5mm), be long enough to bend for MTB use with long stays, thick enough to handle disk brake forces and, lastly, be butted. The look of a fast and abrupt taper is something I like. It just looks strong. The current crop of 7/8" round stays are really not up to the task. The first set of stays that arrived had the butting location wrong and were a touch too thin. They were a good start but wrong. The issue was we needed to pay for some new tooling to get what we wanted. The second batch (after tooling change) was great. They are strong but not heavy, bend great and have the butts in all the correct places.

Currently they are for my use but I assume Lon will eventually put them in the catalog. They come straight which will be hard on some builders. Bending a 7/8" stay for a tire is a tough bend. It requires a good amount of force. Here is a photo of the first set getting put in a bike:

More photos after I weld this bike.

Does that help?

Cheers,

Drew

-

Re: Engin Cycles

Re: Engin Cycles

Drew,

Very cool project. I applaud you for taking the initiative to have made what you can't buy. This is not meant to be sarcastic at all; it is purely a face value question. Does having such a large dimple at the exact point of the tire bend compromise a very large percentage of the round chain stay premise? Is it in such a location on the stay that it's not really a weak spot?

Tony

Anthony Maietta

Web Site |

Blog |

Flickr

"The person who says it can not be done, should not interrupt the person doing it."

-

Re: Engin Cycles

Re: Engin Cycles

Originally Posted by

anthonymaietta

Drew,

Very cool project. I applaud you for taking the initiative to have made what you can't buy. This is not meant to be sarcastic at all; it is purely a face value question. Does having such a large dimple at the exact point of the tire bend compromise a very large percentage of the round chain stay premise? Is it in such a location on the stay that it's not really a weak spot?

Tony

Tony,

In all effect I guess you could call the stay once in its final state is a round oval round stay. Where it connects to the BB it is definitely still round. The dimple is done with an extremely large die and it leaves a very gradual imprint. It is also done with a 3 1/2 ton press and the tube is backed up with a die. The tube is thick enough to handle the deformity and the actual deformity is done in a controlled environment. I have put that dimple in hundreds of stays and it has been done to millions of bikes so I am not concerned about it strength. The tire clearance I am going for requires a dimple on an oval chainstay as well so no matter I need the dimple.

-Drew

-

Re: Engin Cycles

Re: Engin Cycles

Awesome, although I'll admit I was hoping for a KVA s-bend.

-

Re: Engin Cycles

Re: Engin Cycles

Originally Posted by

edoz

Awesome, although I'll admit I was hoping for a KVA s-bend.

Eric,

Funny you should say that. The deal is Joe and I have committed so much time into the oval chainstay thing it was hard to let it go but here is the solution. KVA is going to match the stay in stainless and allow for me to have the same exact stays in both steel and stainless. They are also working on the 19mm seat stays. The goal is to offer a complete stainless version of my current mtb model. The key in my mind is the taper and how it only goes to 15mm in about 80mm's length. All my drop outs are Paragon and have around a 17mm tab, with a 15mm tip it is a perfect march. The next thing is Joe is willing to re-work a new 7/8" stay to work for this mtb use and not try to use the road stays. Hopefully by the end of the year!!

Cheers,

Drew

ps-I am going to bend some stays for Joe's inventory so he will offer some s-bend seat stays.

-

Re: Engin Cycles

Re: Engin Cycles

That rocks so hard, I'm wondering if Lemmy is training you to be the man when he's gone.

By the way, what's the thickness on those stays?

Last edited by edoz; 05-15-2011 at 07:13 PM.

-

Re: Engin Cycles

Re: Engin Cycles

Originally Posted by

edoz

By the way, what's the thickness on those stays?

Eric,

The chainstays are .85mm at the 7/8" end and are that thick til about the end of the 2nd bend. Then .7mm but that is about where the swagging begins so there is very little area that is actually .7mm.

Cheers,

Drew

Tags for this Thread

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Likes:

Likes:

Reply With Quote

Reply With Quote

Bookmarks