Dear Guest,

Please register or login. Content don't create itself!

Thank you

Likes:

0

-

Re: Phantasm Cycle Works

Re: Phantasm Cycle Works

Jay, what part of the process do you enjoy more, building the frame or designing the paint schemes/finishing? Great MTBR story!- Chris

-

Re: Phantasm Cycle Works

Re: Phantasm Cycle Works

Originally Posted by

Dornbox

Jay, what part of the process do you enjoy more, building the frame or designing the paint schemes/finishing? Great MTBR story!- Chris

Man, I really wish I knew. I read this last night and decided to think about it for a bit before answering. I still don't have a better answer.

I really enjoy the whole process. I design my stuff in a parametric solid modeling system (very similar to Solidworks but a fraction of the cost) and I really enjoy that portion. It lets me visually see how the complete bike (I model all the components too, even have spoked wheels, everything but knobby tires) will look before I ever touch a file. Then, from there I can tweak the bike and make sure that I will get exactly what I had planned for. From there, I print the full sized 2D print and that really is the start of the build to me because I can hold something in my hands. Getting the print from Kinkos is always exciting. The last frames, I've started by carving the seat tube sleeve and getting the "P" in it. That is part of the DNA for a Phantasm frame and it's a great way to start. I'm happy to see that finished and it's a great hour or two spent. Cutting the first miter and joining it to reinforces the commitment that I'm well into a new frame. I could go on and on, but each step of the way is very satisfying in it's own way and I relish in each step of the process, each time a tube is tacked and then welded to the next.

Paint schemes are something I enjoy but are not as tangible right away. I like to think them up over time, over time. I've got a dozen paint ideas for different projects in my head right now. Some are simple, some are massively complex, but each lives in my head and not on paper. They are harder to put on paper and don't do well as a solid model. The pictures of the last frame that was at the Texas Custom Bike Show were a paint scheme that was in my head for almost 2 years that is now finally on a bike. It's not exactly what was in my mind as I still wanted to save that scheme, so it's a modified version but for the most part, it's the same scheme and one I will recycle for a future frame that has some other features that didn't make it into this one.

It would be cliche to say that I enjoy the first ride on a new frame the most I suppose, but I really do enjoy that a lot too. All in all, I just enjoy the process from the start to the finish.

It may be easier to answer what I don't enjoy. I don't enjoy waiting on FedEx and UPS to bring tubes, braze ons, dropouts, etc. I don't enjoy running out of Argon. The most frustrating thing is being in a great position and not having another sharpened tungsten electrode. I don't like a messy shop or a gust of wind on a still day when the doors are open. I don't like that soaking flux off a shiny tube makes it a rusty tube. Metal splinters that I have to pull out with my calipers bother me. Those are probably the big ones.

Thanks for the question and I'm glad you enjoyed my story.

-

Re: Phantasm Cycle Works

Re: Phantasm Cycle Works

Originally Posted by

PCW

Man, I design my stuff in a parametric solid modeling system (very similar to Solidworks but a fraction of the cost) and I really enjoy that portion. It lets me visually see how the complete bike (I model all the components too, even have spoked wheels, everything but knobby tires) will look before I ever touch a file. Then, from there I can tweak the bike and make sure that I will get exactly what I had planned for.

That reminds me of when I was an architect. I'd have art on the walls and glasses on the counters. I was the 3D master in college and at the firm I worked at. Love it!

Originally Posted by

PCW

I don't enjoy waiting on FedEx and UPS to bring tubes, braze ons, dropouts, etc. I don't enjoy running out of Argon. The most frustrating thing is being in a great position and not having another sharpened tungsten electrode. I don't like a messy shop or a gust of wind on a still day when the doors are open. I don't like that soaking flux off a shiny tube makes it a rusty tube. Metal splinters that I have to pull out with my calipers bother me. Those are probably the big ones.

Amen with a double amen on the Tungsten... I sharpen a couple dozen at a time. Great reply!-Chris

-

Re: Phantasm Cycle Works

Re: Phantasm Cycle Works

Jay, keep some good tweezers in your tool box.

-

Re: Phantasm Cycle Works

Re: Phantasm Cycle Works

Read through the thread and enjoyed it. Felt like it deserved a bump.

-

Re: Phantasm Cycle Works

Re: Phantasm Cycle Works

Earl, thanks for the bump on this. I hope you're still following this thread after all this time, after I've been away from Velocipede for so long. This is going to be a long read but it’s been a year in the making.

I remember the day you posted this, 9/8/2011 very well, or as well as someone heavily medicated could remember. See, the day before your post, I had just undergone an emergency knee surgery.

Today, the Tuesday after Labor Day is a year later on what has been a very long year for me. Last year, the Tuesday after Labor Day (September 6th, 2011) was the first really beautiful day in a long time here in North Texas. We had 71 days above 100 degrees and 40 of those were consecutive with very little rain. However, that day, September 6th was beautiful. The high was in the mid 80s and the humidity was close to nothing. The skies were clear and clean from a cold front and conditions were exactly what I like when I ride—not too hot, not too cold.

I tried to arrange a MTB ride with some buddies but had no takers. I was going to ride by myself but found a flat rear tire and picked the road bike off the rack and headed off on my standard 30 mile route from the house to the lake, around and back. I was having a great ride until I approached a construction area that has taken our multi-use path out of commission for well over a year. Instead, I took the uphill detour through various parking lots avoiding the gravel, shards of glass, potholes, etc. and crossed over the new highway into the next set of parking lots as I descended toward the lake. I’ve ridden through without incident plenty of times until that day.

I got caught in some gravel and managed to keep the rubber side down before approaching a pothole that looked like it had eaten more than a few wheels only to bunny hop that before ending up in more gravel. By then, I’d covered more ground than I had anticipated and was approaching a curb that was in front of a billboard with more speed than I cared for. It was already too late and as my head was sure to strike a metal pipe holding the billboard in the sky. I realized I need to lunge the bike or I'd be brain damaged. I did just that and took the brunt of the impact on my left side. I really thought I’d broken my arm in the process as I laid there gathering more and more cyclists around me. I remained conscious through the entire thing but as I laid on the ground listening to the sirens of the Dallas Fire Department ambulance grow louder, I thought to myself, “this is going to f--- up my engagement.”

Only a few weeks earlier, I’d commissioned a Boone titanium ring engagement ring for my girlfriend of more than 7 years. I even had the planned engagement date (the following week) engraved inside of the band and shown it to her father when I asked his permission. Then I thought to myself, “man, they’ll have me in a cast and I’ll be out of the hospital in a couple of days tops!”

Rings.jpg

Luckily for me, one of the folks on the scene was a mechanic at the LBS that I build wheels for and said, “I’m going to take a picture of this, you’re going to want to see it later—just let me know when you think you’ll be ready.” I was rushed to the emergency room and spent the rest of my evening and all night on a morphine drip to dull the pain. The following day I was in surgery not for a broken arm, but for my knee which hadn’t really been bothering me all that much right when the accident happened.

The reality of what happened was starting to set in on the 8th, the day of your post. I’d broken my collar bone (left side), a small feat for any cyclist. But my impact was hard enough that I fractured the shoulder blade too. I’d also shattered my left knee cap. The 8th was a terrible day for me and the subsequent days weren’t looking too bright either. That Saturday, the 10th, I was transferred to in-patient rehab mostly because my post-op rehab the past couple of days wasn’t going so well.

The reality that my engagement was going to be f’d up was setting in. I hadn’t had a real shower in a week. However, I was able to get the right folks to do the things I needed to get ready for the first part of that week. I got the orderlies to get me bathed, got someone to fetch the ring and deliver it to me, I even got the music I needed on my tablet and tricked my bride-to-be into bringing me a special dinner that night that we shared in the most romantic place I could find in the building. Of course, she said yes.

After another week, I finally heard the best word in the English language imaginable for a patient in my state. Discharged.

I was still in a wheel chair and couldn’t do anything for myself really. The doctors told me that I couldn’t even touch my left foot to the ground for another 6 weeks and with the broken collar and shoulder blade, crutches were impossible to use. I started going to physical and occupational therapy three days a week and after a few weeks, I was finally able to use a walker and ditch the wheelchair and even start to drive again! About a week later, I was using a cane that I built from 5/8x0.35 seamless Ti and a hunk of zebra wood I had laying around.

cane.jpg

Walking with a cane after using a walker for so long was like turning 16 and passing a driving exam. My wheelchair with my leg locked into full extension was difficult to maneuver and the walker was only marginally better, but the cane, I could go anywhere with my cane. It was finally time to head to the LBS and see my mechanic friend—I was ready to see that picture.

knee.jpg

As you can imagine, I wasn’t ready to see that. It sparked a very emotional reaction because I realized how lucky I was to even be alive, much less walking after the accident. I saw so many people in rehab that had been through so much more than I had. But I was better for the most part with a fantastic prognosis moving forward.

Throughout the process of healing, we’d been planning the wedding and I was still going to both physical and occupational therapies three days per week throughout the remainder of the year and well into January. My PT had the objective to make sure that I’d walk down the aisle of my wedding in February and boy did she deliver:

Hitched.jpg

I was able to start working full time around the beginning of this year and have been playing catch up both at work and at home. I also started to ride my bike again and do “normal” activities. It’s been a wild ride and one I hope to never have to go through again. Part of my recovery was to work in the shop as much as I could. It turns out, that’s the origin of occupational therapy—many folks that were injured were taught things like woodworking and metal working (from what my OT tells me). I started small, arranging the shop the way I wanted, then moved onto hanging new air lines and air drops, installing shelves, etc. Finally, I started doing some woodworking projects and even metal working.

That brings us up-to-date for the most part. A couple of weeks ago, I logged into this forum for the first time and as you can imagine, the first thing I thought was “how old is this bump” only to see that it was that day, the first real day of my recovery, a process that will probably go on for the rest of my life.

So what’s next for Phantasm?

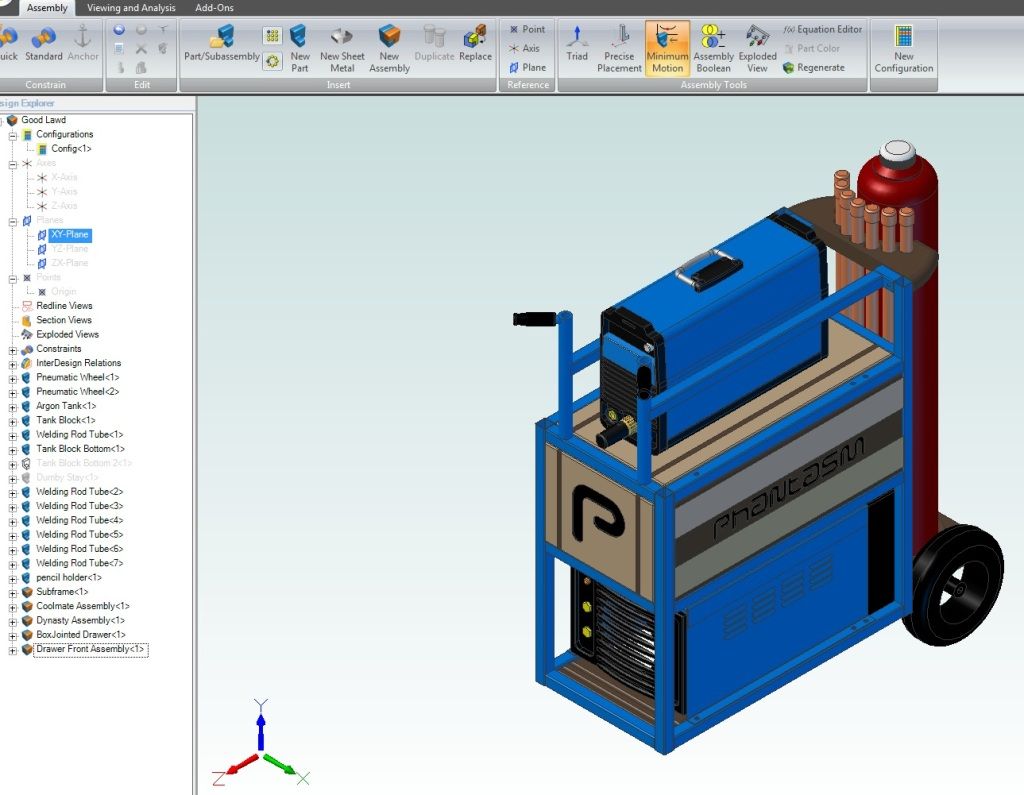

Well, I don’t know to be honest. I know that I am ready to start a new bicycle project. I just finished one of my very last shop projects and that was to create a welding cart for my new Dynasty and Coolmate 3.5 (I think the Coolmate 1.0 that generally comes with the Dynasty is too loud so I went with a bigger and much quieter cooler). The two disparate welding parts required something custom to work right. I also required them to be long and skinny to fit in a closet in the garage when not being used. I also really wanted a drawer for things like cups, lenses, helmet, gloves, etc. so I made that too and even tried my hand at carving a bit. I still have a hose that I need and some clean up to do on the torch hoses, but it's 99% done.

CAD Model:

Front:

Side:

Drawer:

Stainless ground clamp holder:

Various others:

In a lot of ways, I feel as if I’m staring from where I was two years ago when I was first Smoked Out to begin with. In some ways, I’m disappointed that I’m not further along. In other ways, I’m stoked to be headed forward and know that I weathered a terrible storm and came out of the other side ok, not totally unscathed, but ok.

Thanks again for the bump and I look forward to participating on Velocipede in the weeks and months and years to come. But just for good measure, I’m not going to go ride my bike tonight. I may just hang around in the shop and have a celebratory beer.

-

Re: Phantasm Cycle Works

Re: Phantasm Cycle Works

Hey Jay - Welcome back on board atmo!

-

Re: Phantasm Cycle Works

Re: Phantasm Cycle Works

-

Re: Phantasm Cycle Works

Re: Phantasm Cycle Works

Thanks, guys. It's been a fun past few weeks. I started on a new frame on September 21st and it's already at the painter. What was really fun with this one is that I just worked on it a couple of hours at a time when I was waiting for finish to dry on a table I've been working on and some Poly that I've been spraying house doors with. It was just a little here, a little there, and suddenly I ended up with a frame that was done--in less than a month.

I also tightened up some processes around the shop this go around.

Drew (Engin) helped me with my sequence a bit since I'm now using a Bringheli jig instead of the Blanchard ground surface of my table saw.

Glenn (Daltex) really helped me along with intricacies of building a straight rear end on said jig. That alone took more time than the whole rest of the frame did I'd bet if I were tracking time. I made some supplemental tooling as a result of this and I think it's going to help reduce the chainstay time significantly next time.

The guys at Cycle Design helped by giving me free samples of the LFB and the Stainless light fluxes at the Austin show along with the LFB rod. I was surprised how quickly they just rinsed off instead of needing the soak time I was used to with the LWS fluxes and already ordered full tubs. And sure enough, I got home yesterday and had a box of flux from DaveB at the door.

Mr. Sachs helped without even knowing it. I had everything on the frame done except for the braze-on front der. hanger and wouldn't you know it, I couldn't locate the one that I purchased for this frame. It was really nice too, pre-polished stainless steel from Nova. I was planning on making a really nice jig so that I could put it on cleanly but it just didn't happen--the damn thing was lost. Luckily, I called Glenn and he had a couple of hangers just hanging around the shop (pun intended) and said I could have one. They were Richard's hangers and have a little peg (I call it something else) on them so that you can pre-drill the seat tube and just press this thing on. I monkey'd around on his site for a bit, found the prints to it to verify that the bump was indeed on the center line of the tube, and put that sucker on with no drama at all. Super slick and easy.

Finally, the welding cart that I made myself sure was a pleasure to use. I appreciate being able have the welder out of the storage closet, plugged in, pedal on the floor, torch in hand, gloves on, helmet on, and be tacking in 5 minutes since everything is ready to go. No more looking for tungsten or finding my gloves or cleaning the lens 'cause it's covered in saw dust (now it's in the drawer in the cart and immune to such things). I knew my time spent on the cart would pay off and I really do feel like it paid off almost right away with this frame.

I feel like I could do one start to finish in just one really long day if I was uninterrupted. One day I may do that, but for now, I sure enjoy working for an hour or two and then spending the rest of the evening on something else. That way the frame sort of just builds itself. It lets me think about other ideas along the way in the journey and it doesn't feel like a chore/job/work, just a bit of me time in the shop. Of course, with every frame, you learn something new I suppose. This one was no different and I look forward to what the future frames have to teach me too.

This is also the first to go to paint. It's going to debut at the Texas Custom Bicycle Show (details here):

Phantasm Cycle Works

-

Re: Phantasm Cycle Works

Re: Phantasm Cycle Works

Bump Bump Bump

Jay, post some pics of your new kiddo. Also post some pics of your patented 'Mad Max' style mud-bug boiler.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Likes: 0

Likes: 0

Bookmarks