Seeing the list of builders here on the Smoked Out it gives me great honor to be among them. I have loved bicycles since I was a young boy. As a matter of fact, my wife calls bicycles my other woman. I started my bike career in 1989 as the ‘shop rat’ at Wayfarer Bicycles in New London, CT. I had taught myself how to fix my bikes but I learned even more working at Wayfafer after school building those Treks and Peugeots, stripping tubular glue, and working on stuff that the other mechanics didn’t want to bother with! And, with the shop owner’s sponsorship I would race on the weekends. The racing went well for me with the highlight of winning the New England Mountain Bike Championships in the Jr. category. Because of my pretty decent racing resume, I was offered a frame by J.P. Weigle, who was friends with the shop owner. But the decision to take an offer from Haro after going to the Atlantic City trade show haunts me to this day. I thought the elevated chainstay design and three color neon fade with an evolution headset was way cooler than a Weigle frame could ever be. Young and dumb! Oh well…

Before I graduated high school my Dad was relocated to South Carolina to work at Savannah River Site. I decided to stay with a friend and finish school in East Lyme, Ct. When I graduated I immediately went to live with my Dad in Augusta, GA and I started college at USC-Aiken. When I arrived I found bike mechanic work at Andy Jordan’s Bicycle Warehouse and discovered that I wasn’t college material, so I dropped out and decided bicycles were my destiny. I have been head mechanic at Andy Jordan’s since 1991, and I have grown deep roots in the Augusta cycling community. One of the best things that happened while working at the bike shop was selling a bike to a customer who would end up being my best friend and wife!

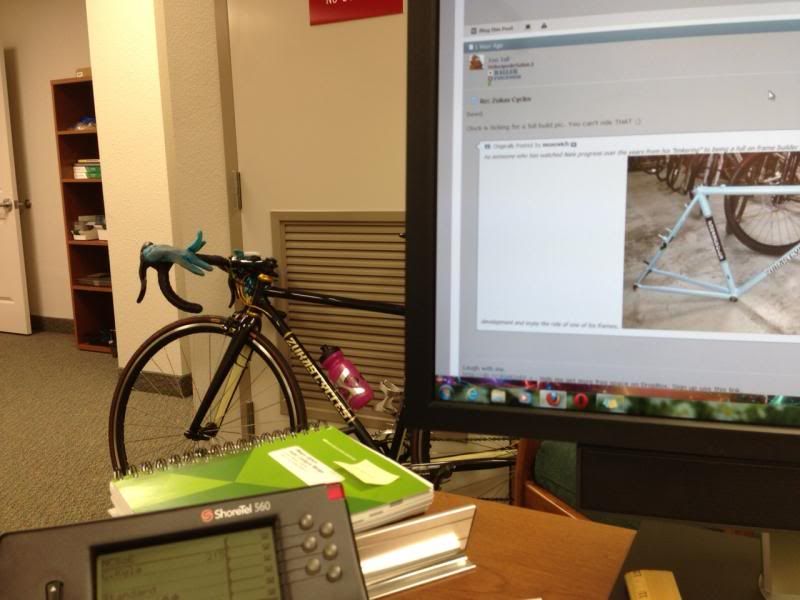

Over the years, I always modified my bikes in some way such as polishing the aluminum parts, completely repainting the bike, or internally routing the cables. These modifications, along with my transforming old Honda motorcycles into café racers, led to some customers suggesting that I should build my own frame. The more I thought about it the more excited I got about solving my 5’7” height, 31.5” inseam issues with custom geometry. So my years of modifying, painting, polishing aluminum, and welding and brazing on bike and motorcycle frames would come into play after I purchased a frame jig. Night after night I would stay up into the early morning studying the Flickr accounts of builders like Richard Sachs, Engin, Winter Bikes and pretty much any builder listed on RS’s site under How Frames Are Made. When the tubing and lugs order arrived, I would sit on the living room couch imagining every move of the file, heating up the lugs, etc. It was time to go for it, and I hit it hard like prom night! Within a week and a half I had a fixed gear frame ready to ride. I remember staring at it in the stand the night I finished thinking I could slam it together and ride it to work the next day. So the next morning with my messenger bag full of lunch, I embarked on my journey. My thought was sink or swim, and boy did it swim! That ride is one of my best cycling memories. On the way home I was quickly reminded of the steel feel and how my fit was the way I always had wished it could be. Ok I thought next is my road bike. Another success with internal cable routing! Then, I just had to do a cross bike for the coming race season. I always had a lust for Speedvagen bikes because of the seat masts. So I built my cross frame with a mast and internal non full length housing. Polished SS lugs and bright lime green paint got the attention of a shop owner at the first cross race. I was about to go warm up when I heard someone say, “Hey, who built that frame?” I never got to warm up and finished almost next to last, but I had an email when I got home to give him a call. He wanted to know if I could build him and his friend identical road frames similar to my cross frame. At that point, Zukas Cycles was born. I started frame building just over two years ago, and I have yet to grow tired of the torch and file. My very small shop space has now been filled with a dedicated paint booth, lathe, mill, vise stand, and tools to enable me to build custom frames one at a time. This is how I intend to keep it to meet my standards for detail and precision. I hope one day to make this full time while continuing to work at the bike shop part time.

Thanks, NATE Zukas

Likes:

Likes:

Reply With Quote

Reply With Quote

Bookmarks