Dear Guest,

Please register or login. Content don't create itself!

Thank you

-

Show me your unicrown fixtures!

Show me your unicrown fixtures!

Bending blades, mitering, all that.

- Garro.

-

Re: Show me your unicrown fixtures!

Re: Show me your unicrown fixtures!

All my stuff here...

Groovy Cycleworks 330-988-0537: Martins 15mm thru axle ti fork...

FWIW, mitering/coping unicrown blades is so much easier on a horizontal mill, had a vertical set up for years with a standing tee-pee fixture, worked but it was less than ideal.

I've also upgraded the bender with a power unit and internal madrel that allows .035 to be bent consistently.

rody

-

Re: Show me your unicrown fixtures!

Re: Show me your unicrown fixtures!

I misread that as UNICORN ...............then i thought about it

-

Re: Show me your unicrown fixtures!

Re: Show me your unicrown fixtures!

Steve,

I assume you are asking because you are looking at changing up your process?

What are you currently using and what are the shortcomings you hope to improve upon?

r

-

Re: Show me your unicrown fixtures!

Re: Show me your unicrown fixtures!

Originally Posted by

Rody

Steve,

I assume you are asking because you are looking at changing up your process?

What are you currently using and what are the shortcomings you hope to improve upon?

r

Well, I was hoping to see some ideas on mitering with a vertical mill, as I just don't have the room for anything else in the shop - lathe, horizontal, nothing - I'm wracking my brain trying to figure out a new floor plan to fit more, but I need extra room to turn around, stuff like that......

Of course I could hand miter them, sure.

I really like the look of a straight blade unicrown, and was hunting for ideas, that's all.

- Garro.

-

Re: Show me your unicrown fixtures!

Re: Show me your unicrown fixtures!

-

Re: Show me your unicrown fixtures!

Re: Show me your unicrown fixtures!

so will the typical right angle milling attachment work on Steve's mill-drill?

-

Re: Show me your unicrown fixtures!

Re: Show me your unicrown fixtures!

You could use a Verti-Vise and Hang it off the edge of the table. We use it all the time at the shop for drilling the ends of large bars.

It also came in handy when I changed my mind and wanted a quill stem.

Adding some threads by FARR Frameworks, on Flickr

-

Re: Show me your unicrown fixtures!

Re: Show me your unicrown fixtures!

Kris, how long does it take you to set up the right angle head?

Thanks,

JG

-

Re: Show me your unicrown fixtures!

Re: Show me your unicrown fixtures!

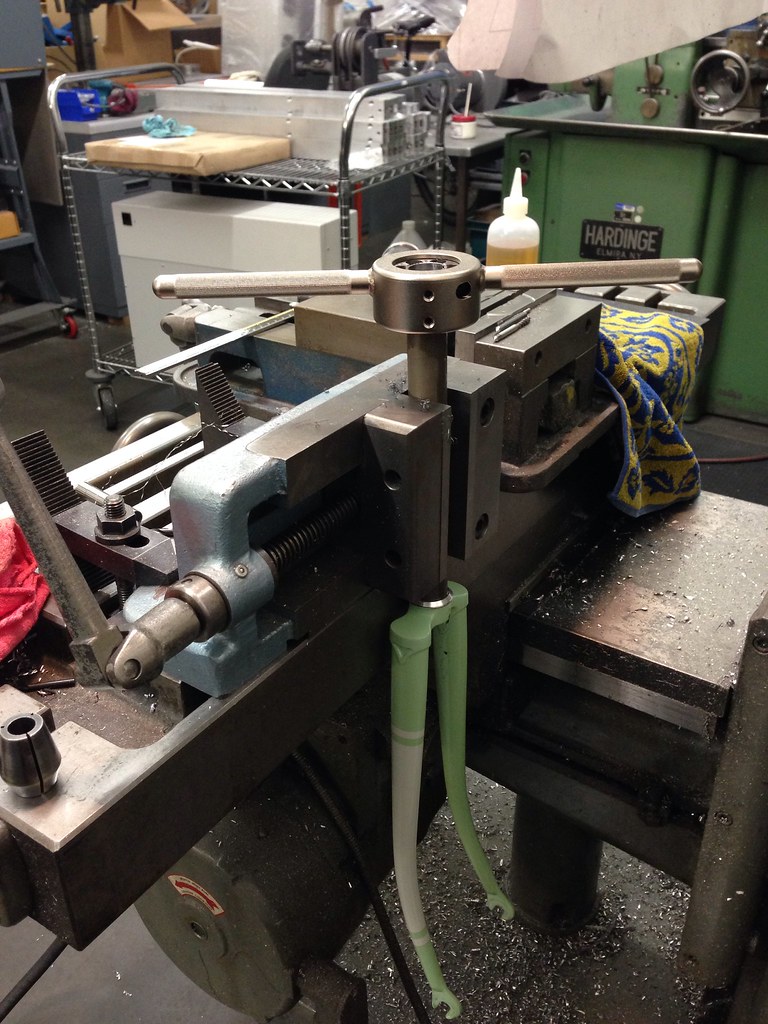

I made this one.. It has swivel that turn to rest on the tube and a pressure plate to hold it down. Seems to hold things well but.. I don't have anything to compare with. I do use it on a vertical mill bolted to a big 90deg block I have with the legs hanging over. I feel your pain with space HaHa!

-

Re: Show me your unicrown fixtures!

Re: Show me your unicrown fixtures!

Originally Posted by

Jonathan

Kris, how long does it take you to set up the right angle head?

Thanks,

JG

if you have a bridgeport and do it occasionally, it's pretty quick. Now I want one, unfortunately my BP is NMTB30, not R8

you need an extra-long drawbar

-

Re: Show me your unicrown fixtures!

Re: Show me your unicrown fixtures!

-

Re: Show me your unicrown fixtures!

Re: Show me your unicrown fixtures!

Steve,

Your limiting factor will be bed to tool space...how much vertical room do you have on your mill/drill to work with if the bed is lowered all the way?

r

-

Re: Show me your unicrown fixtures!

Re: Show me your unicrown fixtures!

Originally Posted by

Rody

Steve,

Your limiting factor will be bed to tool space...how much vertical room do you have on your mill/drill to work with if the bed is lowered all the way?

r

You know, someone back in the thread had a good idea - I have a 2-way on the end for SS/CS fixtures, if I swiveled it to where it was facing away from the cutter........it might work.

I'll look closer today.

- Garro.

-

Re: Show me your unicrown fixtures!

Re: Show me your unicrown fixtures!

one of the long paragon hole saw shafts might work with an upside-down setup. Or a short arbor in a extended collet chuck

-

Re: Show me your unicrown fixtures!

Re: Show me your unicrown fixtures!

Originally Posted by

EricKeller

one of the long paragon hole saw shafts might work with an upside-down setup. Or a short arbor in a extended collet chuck

Exactly what I was thinking.

Thinking this one through before I start fab'ing something up.

- Garro.

-

Re: Show me your unicrown fixtures!

Re: Show me your unicrown fixtures!

Originally Posted by

Jonathan

Kris, how long does it take you to set up the right angle head?

Thanks,

JG

Not counting the first time I set it up... about 2-3 minutes now perhaps? There's an order for this tooling setup which took a some time to do the first time. Now that I know what that is, it's not too bad. My shop is 440 sq. ft. I have room for more machines and if I want I can expand into the back room for an additional 200 sq. ft. but I kind of like the coziness of the shop as it is along with the smaller space to heat in the winter.

There's still room for a tooling room lathe however...

-

Re: Show me your unicrown fixtures!

Re: Show me your unicrown fixtures!

-

Re: Show me your unicrown fixtures!

Re: Show me your unicrown fixtures!

-

Re: Show me your unicrown fixtures!

Re: Show me your unicrown fixtures!

Right on! Glad to see folks mining info and putting it to use.

Rody

Similar Threads

-

By Guillaume in forum The Frame Forum@VSalon

Replies: 2

Last Post: 06-21-2013, 10:48 AM

-

By Adam Eldridge in forum The Frame Forum@VSalon

Replies: 24

Last Post: 10-05-2012, 09:30 PM

-

By VertigoCycles in forum The Frame Forum@VSalon

Replies: 2

Last Post: 09-26-2011, 11:21 PM

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Bookmarks