Dear Guest,

Please register or login. Content don't create itself!

Thank you

-

Re: acetylene vs propane Harris torches?

Re: acetylene vs propane Harris torches?

Originally Posted by

Doug Fattic

...So the line from the tank to the tip would be: a UK regulator, UK flashback arrestor, a 6mm UK hose with one end cut off and and replaced with a Western Enterprises barbed hose adaptor, TM Technologies 10’ ultra-light hose (it has A fittings but they include separate B adaptors that will join the A ends with the B size 40 and 41-B ends on the other hose), “A" size check valves, Victor J-28 or Victor clone (like the Uniweld 71) torch handle, Victor UN-J mixer/elbow and finally a TEN-3 tip (and a TEN-2 and TEN-4 available)...

Hi Doug,

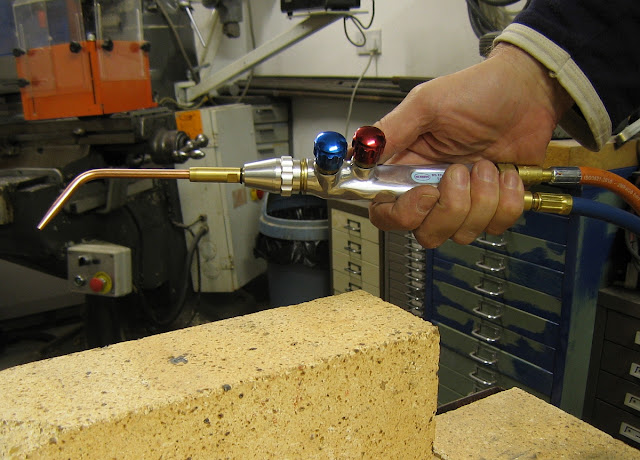

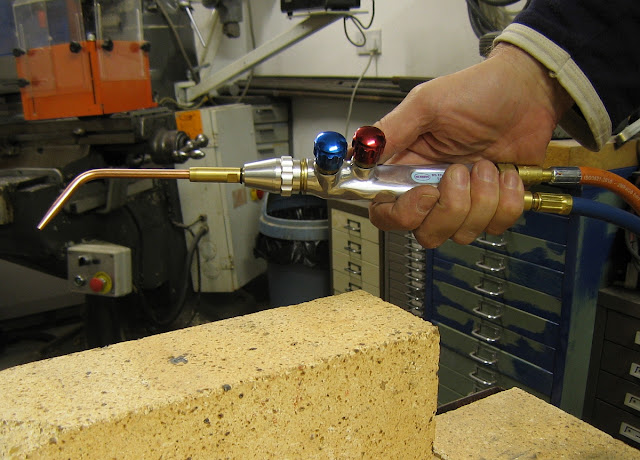

This is the torch I use.

Typical UK lightweight blowpipe (this particular one is from Butbro, but they all are very similar).

It has 6mm hoses fitted with 1/4" BSP check valve at torch end, and 3/8" BSP and 3/8" BSP regulator connection at the other end.

I like the idea of TM Technologies ultra-light hose (although with practice I got better at managing the unwieldy hoses).

Your advice above is for fitting US torches to UK hose. What would be your suggestion for fitting of the ultra-light if I wanted to stay with my UK torch?

thanks,

Chris Kaminski

-

Re: acetylene vs propane Harris torches?

Re: acetylene vs propane Harris torches?

Hi guys, first time poster here, long time lurker. I'm a Mechanical fitter turner with some oxy/acetylene welding, brazing experience and 1 frame under my belt (Part lugged, part fillet brazed). I'm investing in some equipment as I'm in the States on holidays. Using equipment setup by someone else is one thing but buying it and deciding on the setup yourself is quite another. I live in Poland and I've just bought a Victor J-28, along with various tips - Uniweld 17-2 & 3 and some Gentec TEN stuff (elbow and tips) and "A" type torch end flashback arrestors. My plan is to have a Polish tanks and regulators, connected to 6mm tubing with the Western Enterprises adapters mentioned above, connected to a American hose (TM Tech or other) with flashback arrestors at the torch end. I havent included check valves at the moment as I don't know where to include them. I may have been rash buying the torch end arrestors already.

So, are check valves really necessary and if so, where would I connect them in my setup? I don't want to make the rig too fussy with adapters all over the place.

Should I abandon the torch end arrestors and get Polish arrestors at the regulators and get US check valves at the torch instead? Or arrestors to connect the two hoses and check valves at the torch? Any input would be greatly appreciated! I'm not sure if this thread is still active but Doug, any more input into your Ukrainian setup could be useful to me, as I have a feeling they share the same connections. Safety is obviously number one. I'm guessing a flame getting back to the tanks would be pretty much game over but how bad would an explosion in the hose be?

-

Re: acetylene vs propane Harris torches?

Re: acetylene vs propane Harris torches?

If I recall correctly, Doug had mentioned he put the small A size flashback arrestors at the torch end like you intended to do, and then had the check valves in between his B-size rubber hose, and the lightweight TM tech/Smith kevlar hose.

In terms of overall placement, I think it just makes sense for arrestors and check valves to be closer to the torch. Stop the problem before it gets close to the fuel source. Can't offer much advise with the Polish/European connections, but hope this helps.

Tom Lowry

-

Re: acetylene vs propane Harris torches?

Re: acetylene vs propane Harris torches?

So, check valves between the hoses. That seems like a clean option. If I sort the Polish to American before the check valve that could work. Thanks Tom

-

Re: acetylene vs propane Harris torches?

Re: acetylene vs propane Harris torches?

Originally Posted by

duggyballs

Hi guys, first time poster here, long time lurker. I'm a Mechanical fitter turner with some oxy/acetylene welding, brazing experience and 1 frame under my belt (Part lugged, part fillet brazed). I'm investing in some equipment as I'm in the States on holidays. Using equipment setup by someone else is one thing but buying it and deciding on the setup yourself is quite another. I live in Poland and I've just bought a Victor J-28, along with various tips - Uniweld 17-2 & 3 and some Gentec TEN stuff (elbow and tips) and "A" type torch end flashback arrestors. My plan is to have a Polish tanks and regulators, connected to 6mm tubing with the Western Enterprises adapters mentioned above, connected to a American hose (TM Tech or other) with flashback arrestors at the torch end. I havent included check valves at the moment as I don't know where to include them. I may have been rash buying the torch end arrestors already.

So, are check valves really necessary and if so, where would I connect them in my setup? I don't want to make the rig too fussy with adapters all over the place.

Should I abandon the torch end arrestors and get Polish arrestors at the regulators and get US check valves at the torch instead? Or arrestors to connect the two hoses and check valves at the torch? Any input would be greatly appreciated! I'm not sure if this thread is still active but Doug, any more input into your Ukrainian setup could be useful to me, as I have a feeling they share the same connections. Safety is obviously number one. I'm guessing a flame getting back to the tanks would be pretty much game over but how bad would an explosion in the hose be?

1st of all Chris I’ve been researching your situation. I called and asked TM Technologies for their recommended solution. It took some time for them to get back to me and the answer is somewhat complicated so I’ll post what I know about that later. I’m busy with a 3 week framebuilding class right now.

Duggyballs, welcome to the forum. Don’t forget that forum rules for posting in the framebuilding section requires you give your 1st and last name. I’m not a forum policeman/moderator but I personally like and support this rules change.

I’m pleased to hear you got some decent equipment and I’m betting your new setup in Poland will be similar to ours in Ukraine. Since you already have an “A” size flashback arrestor you might as well put it on your J-28 torch handle. Usually I put the check valves there but the arrestors are even better. However you might want to see if your J-28 already come with check valves. Most vendors usually include them with the J-28. Then you would put the check valves (which stops the flow of gas but not fire) on the torch handle and the arrestors between the hoses.

The typical place for a flashback arrestor (which stops a flame) is right before the pressure regulator. The reason for this is just in case your flame or hot dripping flux burns a hole in a hose, it stops a fire before it reaches the tanks. In Ukraine I put the arrestors between the 2 hoses figuring the 2nd hose is not close to my flame so the chances it will catch on fire are slim. That was because I didn’t know the quality or where to buy Ukrainian arrestors. Like I said, if you already have check valves with your J-28, I’d but your arrestors between the hoses. You will also need a male/male connector to make it all work between the hoses. If you didn’t get check valves with your torch handle, you may want to consider Polish arrestors and put them on the regulator to stop a hose fire.

Like you said, your “A” size flashback arrestor is designed to go on the torch handle. For others listening in, keep in mind that there are 2 kinds of arrestors. The one that is designed to go on a regulator has its female end to fit the male fitting on the regulator and has a one way only flow going to the male end that fits onto the female hose fitting. A torch handle arrestor has the flow going the opposite way from male to the female end. So neither one will fit on the other end of the setup without some serious adaptors.

Just to be clear, in Ukraine I have Ukrainian regulators, Ukraine hoses with one end connected to a regulator and the other end cut off and replaced with a size “A” male Western Entreprises American fitting. So one end of the WE fittings is a barb that fits into the Ukrainian hose and held securely with a hose clamp. The other end is a male fitting that goes into the female end of an American flashback arrestor. A TM technologies hose (which comes with A size fittings) attaches to the arrestor. The other end of this light hose attaches to an “A” size check valve that attaches to the J-28 torch handle.

I highly recommend the TM Technologies hose. They come with “B” size adaptors for their “A” fittings if they are needed. They make brazing easier – especially for beginners – but more comfortable for anyone. TM Technologies has a variety of hose accessories and fittings in their catalog.

I’m heading over to Ukraine in September. Poland isn’t that far away so make plans to visit me while I am there! (if I make it through alive :),

-

Re: acetylene vs propane Harris torches?

Re: acetylene vs propane Harris torches?

Originally Posted by

Doug Fattic

1st of all Chris I’ve been researching your situation. I called and asked TM Technologies for their recommended solution. It took some time for them to get back to me and the answer is somewhat complicated so I’ll post what I know about that later. I’m busy with a 3 week framebuilding class right now...

Thanks Doug! really appreciate you taking your time to help me (and of course no rush  )

)

One thing that puzzles me with Tinmantech hoses is that according to them ID/bore of the hose is 1/16" (need to double check it with them).

The reason I questioned it, is that one idea I had was just to get the hose without fittings (Kent was happy to do that) and fit BSP fittings locally here in UK, but of course I couldn't get anything for 1/16" bore.

Chris Kaminski

Last edited by Dave Anderson; 08-19-2014 at 12:08 PM.

Reason: added signature

-

Re: acetylene vs propane Harris torches?

Re: acetylene vs propane Harris torches?

Doug, Thank you for your very thorough reply. It filled in a few gaps in my understanding of all this. Thanks for the heads-up regarding forum rules. I'll have a look at my settings and change my name. I'll also keep others posted as to how my final setup turns out. I'm only back from the US September 23rd so I probably won't make it to Ukraine but maybe next time!! It's really interesting what you're doing there. Be safe.

James Duggan

Krakow

-

Re: acetylene vs propane Harris torches?

Re: acetylene vs propane Harris torches?

Just had a clarification from Tinmantech and the ID of their ultra lightweight hose is .112" (not 1/16" as originally advised) and they are using fittings with 1/8" barb.

I should be able to get 1/4" BSP female fittings with 1/8" barb to connect to this hose - off to search for them ....

Chris Kaminski

-

Re: acetylene vs propane Harris torches?

Re: acetylene vs propane Harris torches?

Hi again, another question for you knowledgeable folk. I managed to find all the suitable connections to complete the Polish-American conversion but it depends on using my torch end arrestors to join the 2 hoses. Is this OK to do or would I need to use a regulator end Arrestor? I'm simply not sure if there's any flow issues. Naturally I'm taking into account the direction of flow. The reason for using a torch end arrestor is that I'm finding the western Enterprises barb to male adapters (40-B & 41-B) can take a long time to deliver and I can't seem to find "A" version of the barbed adapter Doug said he uses in Ukraine. So I'm forced to source another adaptor with a standard female hose ending. Does anyone perhaps know the product code or have a link to this Western enterprises A version of the barbed adaptor? It would eliminate my need for a further step down adaptor.

These adapters will fit on the male end of a "B" torch arrestor: http://www.amazon.com/gp/product/B00...?ie=UTF8&psc=1

With a male B to male A adaptor on the female end of the arrestor, Item #AWS-0377: https://www.tinmantech.com/html/weld...e_adapters.php

Followed by the TM Tech lightweight hose.

Chris, sorry if I jumped on your thread and I hope maybe some info here may be useful for you and other Non-Americans in the future.

James

-

Re: acetylene vs propane Harris torches?

Re: acetylene vs propane Harris torches?

Originally Posted by

duggyballs

Hi again, another question for you knowledgeable folk. I managed to find all the suitable connections to complete the Polish-American conversion but it depends on using my torch end arrestors to join the 2 hoses. Is this OK to do or would I need to use a regulator end Arrestor? I'm simply not sure if there's any flow issues. Naturally I'm taking into account the direction of flow. The reason for using a torch end arrestor is that I'm finding the western Enterprises barb to male adapters (40-B & 41-B) can take a long time to deliver and I can't seem to find "A" version of the barbed adapter Doug said he uses in Ukraine. So I'm forced to source another adaptor with a standard female hose ending. Does anyone perhaps know the product code or have a link to this Western enterprises A version of the barbed adaptor? It would eliminate my need for a further step down adaptor.

These adapters will fit on the male end of a "B" torch arrestor:

Dixon OA61 Oxygen Hose Brass Fitting, Coupler, 9/16"-18 UNF Right Hand Female, 1/4" Hose ID Barbed: Amazon.com: Industrial & Scientific

With a male B to male A adaptor on the female end of the arrestor, Item #AWS-0377:

https://www.tinmantech.com/html/weld...e_adapters.php

Followed by the TM Tech lightweight hose.

James

James, my 1st question is did you get “A” size check valves with your J-28? The Western Enterprises part numbers for a A size swivel nut to barb is 14-O for Oxygen and 14 for acetylene/propane. This is what would attach to the cut off ends of your Polish 6mm hose. It is an all-in-one unit that includes the barb and nut. Again, the part numbers are just 14 and 14-O (O as in the alphabet letter not the number zero).

A torch arrestor’s direction flow is from the male to the female end. That means the sequence gets a little complicated if you choose to use your A size flashback arrestors between between the 2 hoses because it requires 2 adaptors. In that case this is the sequence you need. Your Dixon barbed end will fit a Polish 6mm hose and its other American female B end will need to connect to a Female A to Male B adapter (AWS–0215). Next in the line would be the A size male end of your arrester. This is followed on the other end by a Male A to Male A adaptor coupler (AWS-0214). The A female fitting on the TM hose would screw into that coupler.

You could skip one adaptor in that sequence if you found a barb hose end converter (to go into your Polish hose) that was A size (like WE 14-O and 14) instead of the more commonly available B size you choose.

My recommendation is to put your arrestor on the end of your torch handle unless you already have a check valve to go there. This stops any flame coming from the torch. It does not protect you if your flame accidentally hit your hoses starting them on fire. To do that you would need an American regulator arrestor to go between the hoses or a Polish arrestor to go on the regulator to stop a fire from the hoses from reaching your tanks. If you put a Polish arrestor on the regulator, all you need to connect the 2 hoses is a Male A to Male B adaptor (AWS-0377). I didn’t see a barb fitting that fit a 1/4” hose with a female A nut that would allow you to connect the 2 hoses without a male/male coupler.

-

Re: acetylene vs propane Harris torches?

Re: acetylene vs propane Harris torches?

Originally Posted by

bambuko

Just had a clarification from

Tinmantech and the ID of their ultra lightweight hose is .112" (not 1/16" as originally advised) and they are using fittings with 1/8" barb.

I should be able to get 1/4" BSP female fittings with 1/8" barb to connect to this hose - off to search for them ....

Chris, I just finished another 3 week framebuilding class. They ended up with really nice frames (one used my Nikko blank lugs to cut out a unique design) but we had to work late each evening to finish on time. Every student comes with a different foundation of knowledge and skill set that requires a different amount of attention from Herbie and me to get them to the finish line. Whatever, during this last class I didn’t have time to fully research your question until now.

Interestingly you got more information from TM Technologies than I did. When I talked to them he didn’t remember what the exact ID of their hoses were (somewhere around .100”) and didn’t say anything to me about a barb for 1/8” hose working. He did say that they get about a question a week from outside the US looking for how to connect their hoses to other than US fittings. He said people from abroad have something like a 50% success rate and that Australia's percentage is the highest. He also said they would provide their barbs without the nuts in case some other non-US nut will fit their barbs. One of his suggestions was to cut off the offending US fitting from the barb end and silver braze on a suitable foreign one to the stump that is left. The problem is that Western Enterprises has very few barbs that fit an 1/8” hose. Part no. 548, 549 and 550 all have a barb for an 1/8” hose and NPT fittings (pipe) on the other end. So those might work by cutting off and brazing on a new end. The problem is that other 1/8” barbs don’t have an end that will fit anything other than “A” size nuts. A British nut is close to a "B" size nut.

Looking at a Western Enterprises catalog, part number BR-7 and BR- 8 are British size oxygen and acetylene hose nuts for 3/8”-19 BSP threads. They need a BR-17 barbed hose nipple to be clamped into a 1/4” (or 6mm) hose. The only way I can think of how that would work is if you had a machinist turn down the barb so it would fit the TM hoses.

A somewhat clumsy solution would be to attach a British fitting with a very short piece of 6mm hose to the torch handle. WE part number 14-O and 14 could attach to the other end of the 6mm hose. Now you have an American A fitting on the other end of your short piece of hose. By using WE part number 130 for oxygen and 131 for propane, you can attach those ends to the TM light hose. Of course all that brass adds weight but it would give you the advantage of easy twisting without resistance.

I’m wondering if you found any British fittings that go into an 1/8” hose?

-

Re: acetylene vs propane Harris torches?

Re: acetylene vs propane Harris torches?

Originally Posted by

Doug Fattic

Chris, I just finished another 3 week framebuilding class.

Doug, can you contact me through PM? It appears your inbox is full.

Thanks

-

Re: acetylene vs propane UK lightweight torch

Re: acetylene vs propane UK lightweight torch

Hi Doug,

Thank you, for another detailed reply.

I only got more info from TM because I continued asking instead of accepting first answer (which was incorrect  ).

).

I shared it here because I thought it might benefit others.

Problem with barbs ("hosetails") without nuts is that they would still be US standard (UNF nut) and would not likely fit into UK (BSP) nut - seat radius and shank dia are different. BTW I believe it can't be any old barbs either, (for example typically with cone 60deg seats) if I would want to use them with UK gas equipment.

So far I have found one firm in UK, who said they can supply 3mm (close enough to TM 1/8" barb) hosetails to suit 1/4" BSP nuts as used on UK lightweight torch, but it will take few days. If they come up with goods, I will share details here.

Of course spare 1/4" BSP nuts are easy to get here.

That would sort out torch end and would leave me with something to connect TM hose with standard UK 6mm hose.

I could use your suggestion "...ne end cut off and and replaced with a Western Enterprises barbed hose adaptor..."

Or leave non-return valve on my 6mm hose and find 3mm barb with female 1/4" BSP?

My plan would be to not bother with non-return valves between torch and TM hose and leave non-return valve between TM hose and original UK 6mm hose?

I will post an update as soon as I get my 3mm hosetails.

Chris Kaminski

-

Using adapters to connect torch style flashback arrestor to regulator?

Using adapters to connect torch style flashback arrestor to regulator?

First of all, thank you Doug for starting this thread and thanks everybody else for adding information to it.

I am a total newbie when it comes to brazing and this really helped me to gather all the stuff for my first setup...

I found a Harris 15-3 torch on eBay. It came with torch style flashback arrestors but they are the bigger models with B fittings.

The previous owner used B-to-A adapters to connect them to the torch.

The arrestors are fairly heavy though, defeating the purpose of keeping everything lightweight.

Here's my question: Can I turn those torch type arrestor into regulator style ones by using adapters to reverse the connections (i.e. male, female)?

Given that they will be stationary at the regulator/concentrator the additional weight is not an issue and adaptors are cheaper than new arrestors.

I am planning to use arrestors at the torch and the regulator/concentrator.

I would assume this is possible but given the safety when it comes to this, I'd rather double check with the experts.

Thanks and Happy Holidays!

Guenther

-

Re: Using adapters to connect torch style flashback arrestor to regulator?

Re: Using adapters to connect torch style flashback arrestor to regulator?

It is not as simple as one might think. A torch end arrestor’s gas flow can only go from the male end (that attaches to the hose) to the female end (which attaches to the torch). A regulator’s arrestor’s flow would be from the female end (which attaches to the regulator) and out the male end (which attaches to a hose). Their purpose is to stop gas flow going the other direction so they can’t be turned around. If we put the torch arrestor next to the regulator so the flow would be going the right way, then 2 male ends would be facing each other at the regulator and 2 female ends would be facing each other where the hose connects. The only way I know how to put a torch arrestor near a regulator with the gas flow going the right way would be to use a hose (it has female fittings on both ends) to connect the regulator (with a male fitting) to the arrestor (which also has a male fitting). They don’t make a female/female bushing because that is what a hose has. Then we need a male/male coupler between the arrestor (which has a female fitting on the end closest to the torch) and the hose to the torch handle. Since you are going to need a 2nd hose to do this anyway I would recommend getting a TM light hose (with 2 female “A” size fittings) to go on your torch handle and then place your torch handle arrestor between your 2 hoses. The 2 male/male couplers you would need in this case would have one end being a size A to go into your TM hose and the other being a size B to go into your arrestor. They would be Western Enterprises part #230 for the oxygen hose and #231 for the fuel gas hose. The female ends on your old rubber hose would now connect directly to the male ends on your regulator and concentrator.

This setup means your arrestor is the the middle of your old and new hoses. The only problem with this setup, is that if for some reason you cut your rubber hose with your flame there is nothing to stop the fire going to your tank. Of course your hose should be hanging from the ceiling and not dragging on the floor so it is very unlikely the hose behind the arrestor (a TM hose is 10’ foot long) would somehow catch on fire. So your flame isn’t going to be anywhere near your old rubber hose going to the tanks. The only thing left to do for added security would be to put a small A size check valve (or a more elaborate flashback arrestor – there is only one manufactured in that size) between the torch handle and the TM hoses.

If for some reason you didn’t want to buy a 2nd hose, then you could cut off a portion of your present hose to make the 2nd hose. This would require buying new nipples and nuts to make new end fittings. Nipples come in various sizes depending on the ID of your rubber hose. And nuts come in either A or B sizes. A nipple example would be Western Enterprises part #17 (for 1/4” hose). A B size nut example would be WE part #7 for oxygen and part #8 for fuel gas. You can use a hose clamp (2 is probably better) to secure the nipple to the hose. This new short piece of hose would act as the coupler between the flashback arrestor and the regulator. Just to be clear, you would need to buy 4 nipples and 4 nuts (2 propane and 2 oxygen) + 8 small hose clamps. The advantage of this is that there is very little hose to somehow get cut or damaged to catch on fire. However by the time you buy the nipples and nuts and hose clamps you are part way to the cost of the nice TM technologies light hose anyway.

-

Re: Using adapters to connect torch style flashback arrestor to regulator?

Re: Using adapters to connect torch style flashback arrestor to regulator?

http://www.cbs.state.or.us/osha/interps/1992/valve.pdf

I would not install them mid-hose under any circumstances. It's an imperfect world and betting that your hoses won't ever be damaged or leak is unwise.

I'd install reverse flow+flame arrestor units (two functions in one physical unit) on each regulator precisely as recommended by the mfg regardless of any other safety equipment. If you want the additional protection of RF, or RF/FA at the torch end then get the appropriate units to install there.

There are places where deviation from well engineered systems or recommended procedures is reasonable; this isn't one of them.

-

Re: Using adapters to connect torch style flashback arrestor to regulator?

Re: Using adapters to connect torch style flashback arrestor to regulator?

Originally Posted by

GSinILL

I am a total newbie when it comes to brazing and this really helped me to gather all the stuff for my first setup...are fairly heavy though, defeating the purpose of keeping everything lightweight.

I am planning to use arrestors at the torch and the regulator/concentrator.

I would assume this is possible but given the safety when it comes to this, I'd rather double check with the experts.

Guenther

Guenther,

I'm glad you asked these questions; that caused me to re-examine what I was taught and what I thought I knew. The first thing I'd like to say is that I don't consider any members of this usegroup to be experts in oxy- fuel safety, including me. That's not a slam on anyone. The experts are at the manufacturers. They know the hows, and more importantly the whys.

My understanding has long been to place RF/FAs at the regulator since everything downstream of that is reasonably subject to damage, failure or screwup and can be the point of origin of fire. Your questions prompted me to take a fresh look but questions remain for me. Random thoughts, observations:

I still find citations recommending regulator mounted RFFAs but I also see recommendations for torch end placement.

I have read from non-authoritative sources that combo RFFA are required at the torch end andregulator in EU countries. I don't know if that's the case in North America.

I had not considered the potential cause of reverse flow at the torch end but this mornings reading has raised my awareness of the failure modes, and the benefits of RF valves at the torch end.

I have to dash now but at the least I'll be adding RF valves to my torches and will be calling one or two of the mfgs for more info.

-

Re: Using adapters to connect torch style flashback arrestor to regulator?

Re: Using adapters to connect torch style flashback arrestor to regulator?

Thanks Doug and John,

OK, I bit the bullet and got some regulator style FBAs, so no more need to tinker with the ones I have.

@Doug, you pretty much answered my initial question with "They don’t make a female/female bushing" since that rules out to change the connections on the arrestor.

My setup is already with 2 hoses (a "regular" one and a TM one), no arrestors in between.

At the end I will have torch and regulator FBAs and directly connect the 2 hoses with couplers.

One interesting observation, as soon as I talked about "A" size or 3/8 fittings to the folks at Airgas and Grainger, I got the deer in the headlight look.

Pretty obvious that they are not dealing with those very often.

Again thanks for your help!

Guenther

-

Re: Using adapters to connect torch style flashback arrestor to regulator?

Re: Using adapters to connect torch style flashback arrestor to regulator?

-

Re: Using adapters to connect torch style flashback arrestor to regulator?

Re: Using adapters to connect torch style flashback arrestor to regulator?

My post concerning flame arrester/reverse flow preventer placement (hereafter FA/RF) came off a bit brusk and impersonal; I'd like to correct that. A Mulligan, please.

Doug - I understand your rationale for suggesting placement in between the two hoses but in my estimation it compromises safety and offers no advantage to the operator that's not otherwise available while still relocating them away from the torch. Locating FA/RF units at the regulators protects the entire string of comparatively easily damaged hoses and other equipment that are the most likely points of ignition, rather than just a portion of the hose, and it meets your goal of reducing torch weight.

Keeping hoses off of the ground and being mindful of protecting them from damage is good practice, as you noted, but its an imperfect world; they can still be damaged. To wit, I have two sets of Smith Kevlar sheathed hoses that leak; one from a hot particle and the other from a manufacturing problem in fitting one of the end connections. These hoses rarely touched the ground.

The OPs question got me thinking: What is the current state of recommended practice, and what do I not know? What came out of that was an appreciation for, at a minimum, protecting against reverse flow at the torch; inadvertently touching the tip to the work piece or filler puddle, a pop launching molten metal into the tip being potential causes. Those sorts of things can occur, even to experienced folks. Interestingly, I didn't find any definitive statements of regulatory requirements, or even universal agreement on industry recommendations. That said, I'll likely add RF protection units to my torch.

I'd also like to advise newbies to get competent instruction in proper use of oxy/fuel equipment and follow the manufacturer's recommendations as to general procedures as well as installation of safety accoutrements. They've done a lot more failure modes and effects analysis then the rest of us.

Similar Threads

-

By wojtek in forum The Frame Forum@VSalon

Replies: 2

Last Post: 07-07-2012, 02:48 PM

-

By zank in forum The Frame Forum@VSalon

Replies: 12

Last Post: 04-13-2011, 10:35 AM

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Likes:

Likes:

Reply With Quote

Reply With Quote

)

) ).

).

Bookmarks