Dear Guest,

Please register or login. Content don't create itself!

Thank you

-

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

Loving seeing your process afresh, Mark.

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

Thanks Rich.

I'm including a lot of detail as I have made a couple of changes to the process. One which I forgot to flag last week concerns the way the filament winder is used, I'll call it out when the 2nd wind is done on these tubes.

Mark Kelly

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

Originally Posted by

RichTheRoadie

Loving seeing your process afresh, Mark.

I just love seeing the process!

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

Boron

The strange looking semi-metallic sheen is due to a strange semi-metal: boron.

From bottom to top: base tube, boron laterals, shrinkwrapped ready for oven.

Boron is incredibly strong in compression because it is far more resistant to buckling than carbon. This same property means it will not conform to an uneven surface, thus explaining the fuss earlier about making sure everything is flat and even.

Oh, the peg stops the tube rolling, nothing more.

Mark Kelly

-

-

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

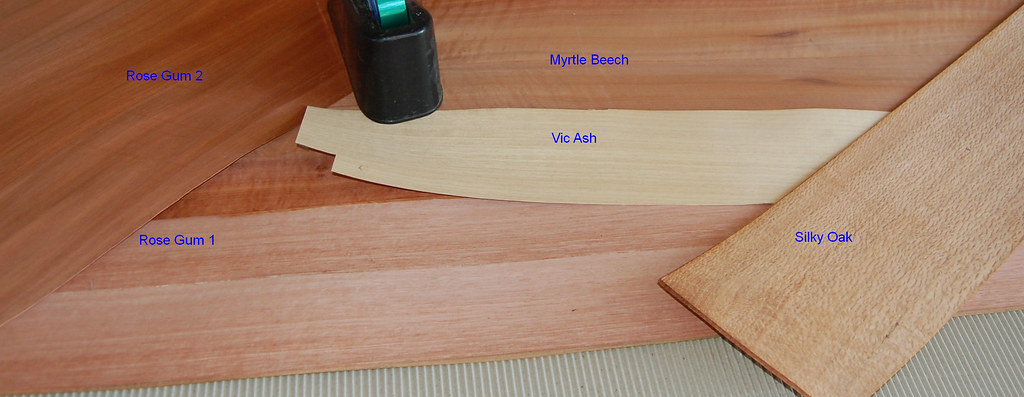

Selection of leaves for outer layers:

Leaves

Mark Kelly

-

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

Meanwhile the main tubes are mitred before bonding, reasons will become obvious later.

Head tube mitres

The green tape is proxy for a 0.1mm epoxy bondline

Mark Kelly

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

Funny, i would have bet good money that you “finalised” the tubes with the timber leaves before bonding them. That’s me wrong then.

I’m very curious to see what happens next!

Colin Mclelland

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

Yes I (mostly) do.

My comment about mitring before bonding was badly written, the mitring is done well before the bonding takes place. I need the mitres within 1mm of where they will eventually be so that the ends of the external leaves can be correctly placed and by the time I get them that close it is easier to just finish the job.

I placed the first leaves today, a pic tomorrow will make some of this clearer.

Mark Kelly

-

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

I realised once I'd unmoulded these that I've created a lovely stress riser at the bottom of the vee on the lateral sides of the tubes.

Time to start again.

Mark Kelly

-

-

Re: Finishing touches

Re: Finishing touches

Transformation,

Lustre

it, not is.

I can spell, really.

Mark Kelly

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

Those glass plates are fragile, and tend to break when they are too slim.

If you can fit it, go get a borosilicate plate 1/4" thick and avoid the pain. You can get a piece custom cut at a glass place. Ask for the same glass they'd use on a fireplace. Honestly, at 100C, you probably won't break a soda glass sheet either, so check the price and choose whichever makes sense.

Also, I like to use hair-spray on the plate to ensure better adhesion. I think it also limits maximum plate adhesion because I haven't broken one in a LONG time. Try Aquanet Extra Super Hold, or anything with an acrylate copolymer if you can't find that one.

Oh, and the lugs look awesome.

Derek Anderson

Army Of Evil Robots – Home Pub Furnishings

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

Thanks for the tips. The glass bed has a flexible heater attached to it, the manufacturer sells them as a pair and sees fit to charge $150 for a $5 piece of glass with a $10 heater attached to it.

If I replace it again I will try your method.

I have solved most of my problems by using kapton tape on the bed and laying the adhesive on it but I will try the hair spray trick.

BTW I love your stuff, whereabouts on the Sunshine Coast are you? My mother lives in Mapleton.

If I may return the favour, most of your problems with epoxy seem to stem from using ambient cure with no vacuum.

Your life will get much easier if you build yourself a temperature controlled box and invest in a vacuum pot. Use a slow cure clear epoxy like ATL R246 ( based on the Gold Coast) with one of their slower hardeners (I can't remember the numbers as I use the fastest hardener as it gives the highest Tg). Mix it well and place it in the vacuum pot and pull it down to full vacuum for 10 minutes. Make up the workpieces and place them in the oven to cure at a profile that suits the epoxy (it will be called out in ATL's data sheet).

Also if you need surface treatment don't sand, scrape. A brand new Stanley knife blade works a treat. Once you have the surface dead flat recoat it with Northane 2 pack polyurethane clear gloss, should be available at your local boat repair place. The Northane can also be scraped flat but make sure it is totally cured first.

Mark Kelly

-

Re: Finishing touches

Re: Finishing touches

Originally Posted by

Mark Kelly

Transformation,

Lustre

it, not is.

I can spell, really.

For some reason I didn't notice any of those...

I can read, really.

Colin Mclelland

-

Re: Lyrebird Cycles

Re: Lyrebird Cycles

Originally Posted by

Mark Kelly

Thanks for the tips. The glass bed has a flexible heater attached to it, the manufacturer sells them as a pair and sees fit to charge $150 for a $5 piece of glass with a $10 heater attached to it.

If I replace it again I will try your method.

I have solved most of my problems by using kapton tape on the bed and laying the adhesive on it but I will try the hair spray trick.

^ That all works too. If you do want to replace that glass, you can usually get those flexible heater sheets on aliexpress for nearly nothing if you want to try home-building it, example: 24V 25mm 2W Square kapton film flexible heater-in Motor Driver from Home Improvement on Aliexpress.com | Alibaba Group , but it might mess with the PID tune for the printer. If the wattage and voltage match, you're probably golden, and there are lots of other elements on that site (click on heater pad on the left side of the listing).

Originally Posted by

Mark Kelly

BTW I love your stuff, whereabouts on the Sunshine Coast are you? My mother lives in Mapleton.

Thanks. Other Sunshine Coast though; we're on the less known one west of Vancouver. Great mountain biking (google the coastal crew).

Originally Posted by

Mark Kelly

If I may return the favour, most of your problems with epoxy seem to stem from using ambient cure with no vacuum.

Your life will get much easier if you build yourself a temperature controlled box and invest in a vacuum pot. Use a slow cure clear epoxy like ATL R246 ( based on the Gold Coast) with one of their slower hardeners (I can't remember the numbers as I use the fastest hardener as it gives the highest Tg). Mix it well and place it in the vacuum pot and pull it down to full vacuum for 10 minutes. Make up the workpieces and place them in the oven to cure at a profile that suits the epoxy (it will be called out in ATL's data sheet).

Ha; just built one this summer. Monster 250 litre chamber that can fit several bar-stool tops. Although it turns out that the wood outgasses badly, even if you seal it in advance :O Still works for de-gassing the epoxy just fine. I'll take a look at that epoxy you recommend though... We're using some furniture specific stuff, but it's open time is only 30 minutes, and it's also VERY sensitive to temperature (22C +- 3 degrees ambient, or it hazes like crazy).

Originally Posted by

Mark Kelly

Also if you need surface treatment don't sand, scrape. A brand new Stanley knife blade works a treat. Once you have the surface dead flat recoat it with Northane 2 pack polyurethane clear gloss, should be available at your local boat repair place. The Northane can also be scraped flat but make sure it is totally cured first.

Hmmm. How nasty toxic is that stuff? I have been leery of a lot of the better polyurethanes because they have terrifying MSDS docs. I would love to find a decent urethane that doesn't sound like it'll melt my eyeballs and give me cancer in one go. Agreed on the scraping. That's my go-to for tricky wood surfaces too, and we have a broad selection of scraping tools/planes.

Similar Threads

-

By Boedie in forum Smoked Out

Replies: 30

Last Post: 11-22-2014, 05:45 PM

-

By magnoliacycles in forum Smoked Out

Replies: 25

Last Post: 04-11-2011, 04:57 PM

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Bookmarks