Cheers Dazza

The rock star is dying. And it's a small tragedy. Rock stars have blogs now. I have no use for that kind of rock star.

Nick Cave

www.llewellynbikes.com

The usual Facebook page

https://www.flickr.com/photos/llewellyncustombicycles/

Darrell Llewellyn McCulloch

Part 9 The Llewellyn Casting Story

Casting design # 2

# XLS. The Crescendo Lug set. (formerly called the “Slant 6 lug set” ) Year of introduction 2004.

Llewellyn # XLS “Crescendo” sloping top tube lug set (formerly called “Slant 6”) was the world’s first sloping top tube lug set for road bikes for XL tube size (DOS) and the first Llewellyn frame lug set that I designed and produced.

In 1992 I received my first Columbus MAX tube sets and this set with its bigger than ever before diameters became popular for track riders and road riders who are big, heavy and or tall. Recently the MAX tube set has a folklore legend grow around it which surprises me as there is nothing magical about the MAX tube set. The tube set had a lot more metal and a lot more grams so it felt very firm under the pedal, however one must remember that it arrived in the era of 28.6mm down tubes and even the larger 31.7mm down tubes had only just arrived so the 35mm MAX down tube along with a larger seat and top tube coupled with larger chainstays and bigger MAX fork blades was going to give a very firm frame and this became the new “magic feeling”.

I built many road and track frames using Columbus MAX tubes but it was very troublesome to build with due to implications with the tube dimensions and shaping and also only suitable for 1” forks. It must have been late on Friday afternoon when the person designed the lugs, BB shell and fork crown for the MAX tube set. There is far too much metal along with very bad tube fits, it all looked more at home bolted onto a piece of agricultural farm machinery than part of a fine hand crafted bicycle frame. These lugs and BB shell thus required a fair amount of rectification work if you were to get acceptable results. Cutting, trimming, milling, filing to remove some grams and give a sweeter aesthetic, but after that it all worked for the stronger, bigger rider or those who desired a firm frame under the pedal

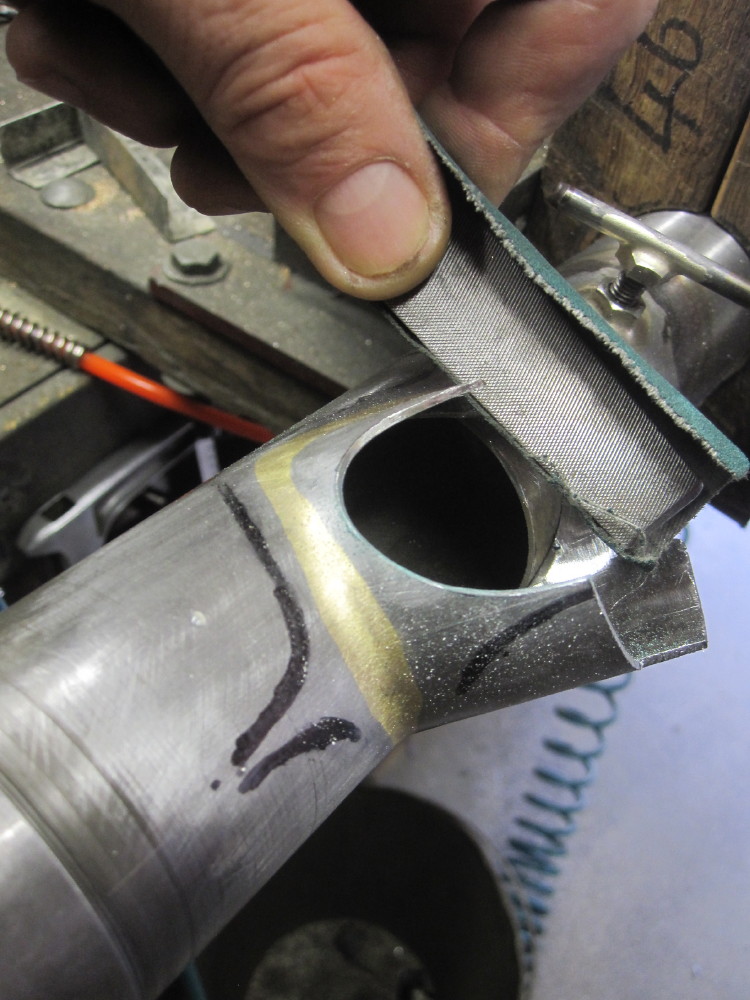

It was 2003 and Columbus had long stopped making MAX tubing and lugs and the left-over supply was finally drying up. With MAX fading I needed a replacement for the big, tall, or solid riders with all the desired features required for lugged construction in the first decade of the 21 st Century. After the enthusiasm and toil of the recently completed “Stem Lug Set” I soon started sketching again. I wanted to use a sloping top tube design for reasons of structural merit, (shorter tubes) and this can also allow the use of a taller head tube in frame designs for riders who need their handle bars higher. A bigger 36mm head tube to fit 28.6mm (1 1/8”) alloy, carbon or steel steerer forks and with XL tube diameters that are the same as MAX. The shaping of the large MAX down and top tube to fit the older smaller head tube was of negative value to the frame, however with the 36mm diameter the lug set was to have round tubes throughout which is a plus for torsional rigidity.

I settled on 6 degrees of top tube slope which is an angle that is useful but not so much as to make the frame look like a BMX bike. There was to be ample stack height on the top head lug so it could be trimmed to suit the frame design if required. The bottom head lug needed to have cast bosses for M5 gear cable adjusters with a counter bore for the adjuster spring to nestle into, so when turned it did not scrape and chip the paint off, thus helping to keep a neat and tidy appearance on the finished frame. Those old style seat binder bolts are just plain dreadful, so it will be a standard stainless steel M6 caphead bolt for the seat post binder boss. The top of the seat post binder keyhole slot was to have rounded corners to avoid digging into and damaging carbon seat posts and thus give a more gentle but secure waist type grip on the seat post. I also needed to design enough room on the lugs for reshaping of the shorelines or extra elaboration if so desired.

I studied the tube maker’s available tubes for a useful selection of tubes. To have the seat post fit directly into the Columbus 31.7 seat tube a 30.60mm seat post was required, thus avoiding dreadful sleeves. My US agent at the time and I organised the manufacture of 30.60 seat posts in the USA. I did more sketches with my shoreline inspiration coming from a Bocama lug set from the 1980’s that I had used back then. I then did the 2D CAD dimensioned drawings and LongShen again did their interpretation from my hand fabricated sample lugs to produce their 3D drawings, however there is a loss of interpretation from my samples to draftsman, then onto the tool maker and to the end result of the investment cast lug. No too bad but to my eyes it is there.

The first of these lugs castings arrived on my doorstep and to my European agent “Ceeway” and to my USA agent in late 2004.

This lug set has been a terrific success for my in-house frame building and these lugs continued to be in production and used by other builders around the world to create nice well designed bicycles. In 2017 there was the addition of an optional socket seat stay fitting seat lug (# XLS-04) but that story is to come later.

Cheers Dazza

The rock star is dying. And it's a small tragedy. Rock stars have blogs now. I have no use for that kind of rock star.

Nick Cave

www.llewellynbikes.com

The usual Facebook page

https://www.flickr.com/photos/llewellyncustombicycles/

Darrell Llewellyn McCulloch

The third Design and Form by Llewellyn casting, Year 2005

#LL-09-318 and #LL-09-35mm down tube gear adjuster bosses. (The Little Fellas)

STI and Ergo gear/brake levers have been the norm since 1992 however for some combinations of frame designs and component selections one needs a neat and functional down tube boss for a gear cable adjuster to nestle into. For many years I was fabricating my own gear bosses from stamped chain stay bridge reinforcements along with stainless steel stock material, drilling, taping a thread and brazing together onto the down tube. This was because to my mind and eye there was nothing available that was functional or elegant but fabricating these bosses is a time consuming chore. This chore was the motivation to set my mind into motion to design and produce a new down tube gear boss. The new boss will use standard M5 gear cable adjusters (stainless steel, of course). It will have a counter bore for the adjuster spring to nestle into so when the spring is turned so the paint is kept neat. The boss needs to be easy to use in the frame construction process and have a decent amount of shoreline footprint to reduce possible stress risers on thin tubes. Remember these would most likely be placed on the thin 0.40mm section of the tube. During my previous casting projects I was finding that there was always a minor loss of interpretation from my fabricated samples and drawings to the CAD draftsman, then from the CAD drawings to the tool maker. I was motivated to learn how to directly generate the part’s 3D CAD drawing for the tool maker to use directly for the construction of the mould tools to shoot the wax pieces in the investment casting process. It was many long nights along with a considerable quantity of weekends as I worked through several text books worth of lessons with the 3D CAD program. I got to a working process with this 3D CAD tool. It was toil but it was for me to move down my time line of acquiring skills and enhancing the details and results of my work.

In early 2005 I did my first casting project that used my own 3D generated drawing. The pencil sketches that are a close reflection of my fabricated versions were followed by the 3D drawing.

This new down tube M5 gear adjuster boss I gave the nick name of “The Little Fellas”. Investment cast in stainless steel down tube.

The shore lines can be altered and the boss polished to provide a detail for some special frame sets.

Cheers Dazza

The rock star is dying. And it's a small tragedy. Rock stars have blogs now. I have no use for that kind of rock star.

Nick Cave

www.llewellynbikes.com

The usual Facebook page

https://www.flickr.com/photos/llewellyncustombicycles/

Darrell Llewellyn McCulloch

What is he building in there ?

what is he building in there ?

And he's hiding something from the rest of us

He's all to himself, I think I know why.................

Cheers Dazza

The rock star is dying. And it's a small tragedy. Rock stars have blogs now. I have no use for that kind of rock star.

Nick Cave

www.llewellynbikes.com

The usual Facebook page

https://www.flickr.com/photos/llewellyncustombicycles/

Darrell Llewellyn McCulloch

Cheers Dazza

The rock star is dying. And it's a small tragedy. Rock stars have blogs now. I have no use for that kind of rock star.

Nick Cave

www.llewellynbikes.com

The usual Facebook page

https://www.flickr.com/photos/llewellyncustombicycles/

Darrell Llewellyn McCulloch

The gig is done, the dust of this whirlwind has settled but the ramifications of the event will rock on till April next year when we all will be back in Melbourne at the table again.

I have attended four shows in the USA and two in the UK and also the first Aussie show iteration in 2012 and in full honesty I can say that the vibe and value of the 2018 HBSA gig is already for me Number 1 of all time.

The removal of show booth war fare extravaganza bull shit that goes on at other shows facilitates and ensures that the spot light is focused and maintained without distraction on the makers and their bikes and or products they make.

No effing dioramas, imitation workshops, or 3.5 tons of timber erected in a booth to look like a log cabin…….. Sigh!

The vibe, the process was as if you are at the Tate gazing at a Turner or a Constable. Appreciating the product, conversing with the maker rather than the shallow “Wow” of a conspicuous marketing budget.

Space around the bikes and products, no walls, no banners was very important. Every bike was displayed on the same show provided plinths. The punters appreciated this and so did the exhibitors. If you were there, you would know that it worked splendidly.

See you in Melbourne 2019.

Cheers Dazza

The rock star is dying. And it's a small tragedy. Rock stars have blogs now. I have no use for that kind of rock star.

Nick Cave

www.llewellynbikes.com

The usual Facebook page

https://www.flickr.com/photos/llewellyncustombicycles/

Darrell Llewellyn McCulloch

The Lugged Colossus is with it's owner in Western Australia and he has started his adventures on it.

It is now a standard model in the Llewellyn Range, however the toil of the hand fabricated lugs due to the largest tubes Columbus make, will be reflected on the invoice.

Cheers Dazza

The rock star is dying. And it's a small tragedy. Rock stars have blogs now. I have no use for that kind of rock star.

Nick Cave

www.llewellynbikes.com

The usual Facebook page

https://www.flickr.com/photos/llewellyncustombicycles/

Darrell Llewellyn McCulloch

Impressive !

Cheers Dazza

The rock star is dying. And it's a small tragedy. Rock stars have blogs now. I have no use for that kind of rock star.

Nick Cave

www.llewellynbikes.com

The usual Facebook page

https://www.flickr.com/photos/llewellyncustombicycles/

Darrell Llewellyn McCulloch

That Lugged Colossus is absolutely bonkers... Awesome.

Chikashi Miyamoto

Cheers Dazza

The rock star is dying. And it's a small tragedy. Rock stars have blogs now. I have no use for that kind of rock star.

Nick Cave

www.llewellynbikes.com

The usual Facebook page

https://www.flickr.com/photos/llewellyncustombicycles/

Darrell Llewellyn McCulloch

Dazza, on the inside edge of the twine finish, what is that thin strip of rubber-like thingy? Mick Peel has done a couple of bar tapes for me, and I was thinking about finishing one of them with linen twine, which is why the last pic caught my eyes.

Chikashi Miyamoto

It is the Nitto Brand Electrical tape. The twin is tight and waxed and it binds and compresses the tapes, but you do not go to close to the edge, hence a bit of tape showing.

Mail your cheque to the World Wide Head Quarters of Llewellyn Everton Hills Queensland.

Busyman tape on the Blue bike at the HBSA

Cheers Dazza

The rock star is dying. And it's a small tragedy. Rock stars have blogs now. I have no use for that kind of rock star.

Nick Cave

www.llewellynbikes.com

The usual Facebook page

https://www.flickr.com/photos/llewellyncustombicycles/

Darrell Llewellyn McCulloch

Dazza do you think you’ll end up sending drawings of the colossus lugs to LongShen for production? You’d be first to market :)

I would like to think so, however the costs of the tooling against sales to other builders is the hand brake as my in house production is not enough. I have Columbus all set to make the butted 32.7mm seat tube.

I have OS socket seat stay seat lugs in the pipe line, I want new BBs with better angles to reduce the amount of rework time, disc brake drops and a chainstay to match, and better fork crowns. I wonder if the people who design fork crown castings have ever made forks them selves. I have spent $ on 3D printed waxes and tested local foundries who fail to cast such thin castings. It can be done but the qty required is the stopper. Before anyone tells me that 3D printing is the answer, do your sums and research, it cannot do everything and anything at a price that can be realistic. (well not yet) With only 10 years or less till I slide into my oblivion of frame building relevance, it all costs much more than can be recouped. This is my chosen path of professional expression, so I have to be pragmatic, so lug fabrication a couple times a year it will be.

Cheers Dazza

The rock star is dying. And it's a small tragedy. Rock stars have blogs now. I have no use for that kind of rock star.

Nick Cave

www.llewellynbikes.com

The usual Facebook page

https://www.flickr.com/photos/llewellyncustombicycles/

Darrell Llewellyn McCulloch

Wow ! That is one fine looking bike indeed.

It is a good inspiration for any builder.

I love the ridge on the bottom of the headtube to keep the cables from wearing the paint.

But that is just one of the millions of details.

The whole picture is what is impressive.

What a pretty bike !

I bet it rides great, too.

Dazza,

Your are inspiring.

Thanks for posting all that you do.

-Mark

Mark Walberg

Building bike frames for fun since 1973.

Cheers Dazza

The rock star is dying. And it's a small tragedy. Rock stars have blogs now. I have no use for that kind of rock star.

Nick Cave

www.llewellynbikes.com

The usual Facebook page

https://www.flickr.com/photos/llewellyncustombicycles/

Darrell Llewellyn McCulloch

Bookmarks