Magnification

A cheap plastic Fresnel lens solves the legibility problem.

Purge Hoses

I decided to integrate purge fittings now rather than having to retrofit later.

Purge well

So I cut annular wells into the support arms beneath the contact points, then drilled and tapped a gallery hole for a BSP gas fitting. On this arm I changed my mind about which direction I wanted the hose to face so I plugged the hole.

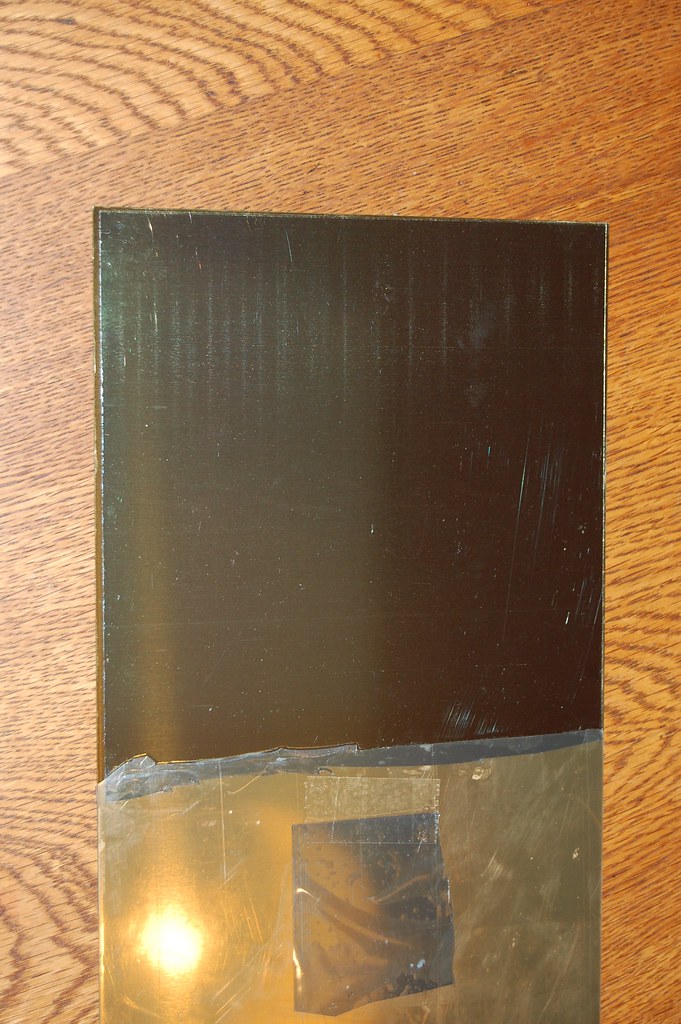

Purge disc

The support discs are stacked laser cut 5mm stainless plate, the vent holes placed to align with the well in the support arm. The design should help reduce the turbulence in the gas as it enters.

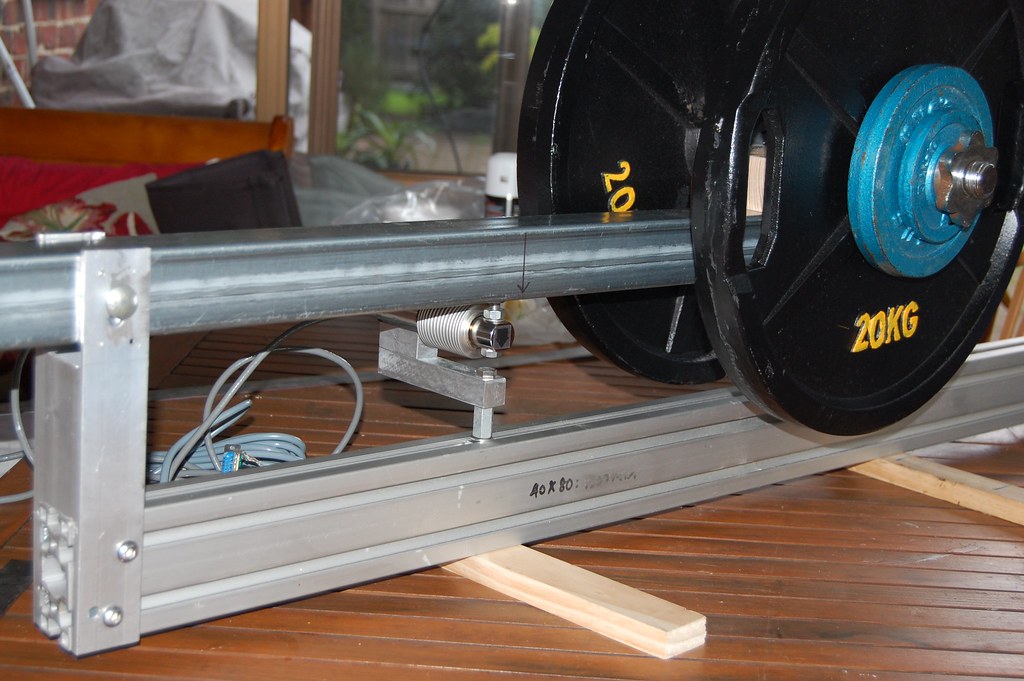

BB Assembled

The BB post uses a similar arrangement

BB Discs

Two of the holes are used to rivet the discs together using 6mm Ti tube leftover from the bottle cage project: gotta love the idea of titanium rivets. One of the discs for the outer puck has only these two rivet holes, these are tapped for M5 grub screws to prevent the gas escaping out the holes.

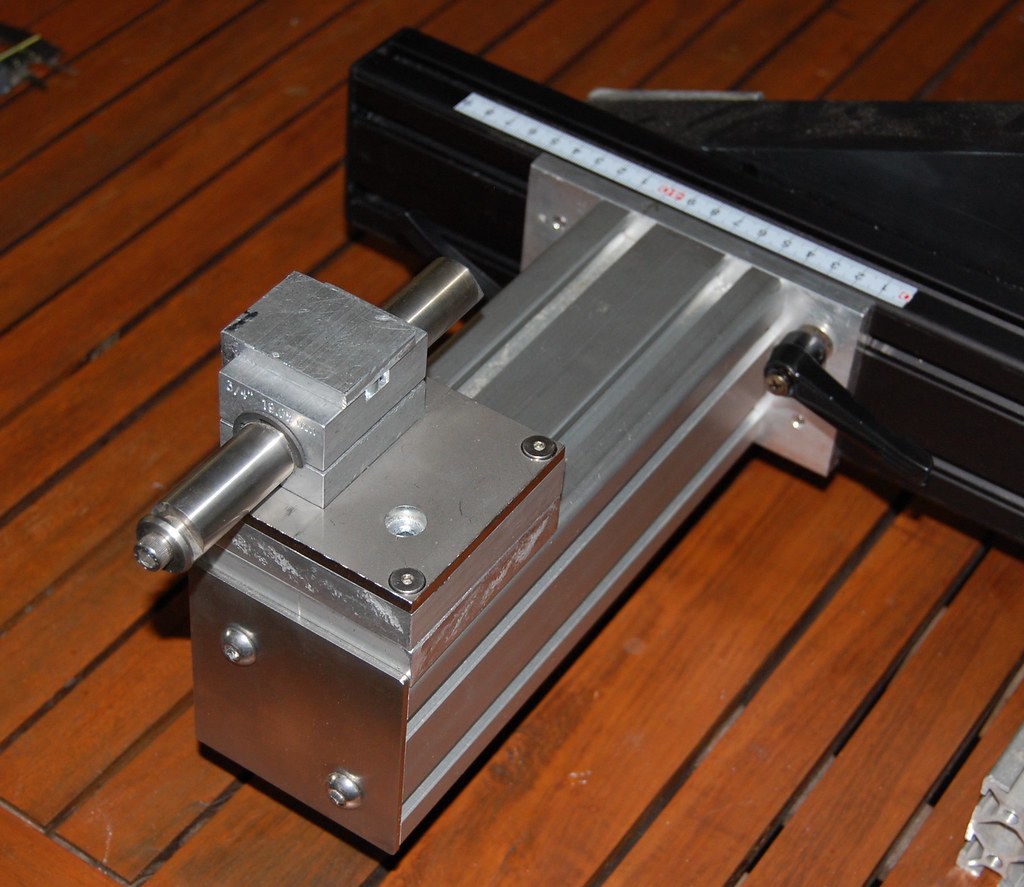

Rear Arm

After chopping and changing on the rear arm design I went with simplicity on the grounds that less interfaces mean less misalignment, it also reduces the number of pieces that need to be machined: the two 16mm blocks shown are placeholders for a single machined block which will have alignment grooves on the bottom surface.

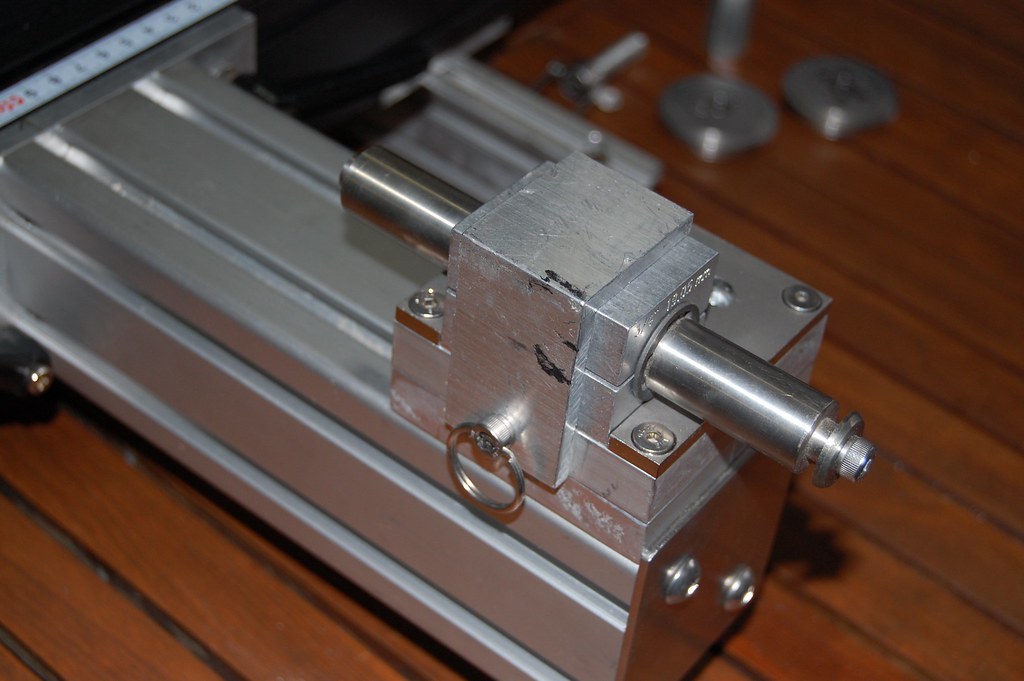

Rear Arm 2

The dummy axle is off the shelf from Alex Meade, the dummy axle holder is a tube block off the shelf from PMW.

Rear Arm 3

The idea behind this arrangement is that the dummy axle and its holder stay in the frame, so there's a simple mechanism to allow release and realignment. This gets over the problem I had with the previous system (from Alex Meade) where I needed to realign the dummy axle every time I took the frame out of the jig.

Likes:

Likes:

Reply With Quote

Reply With Quote

Bookmarks