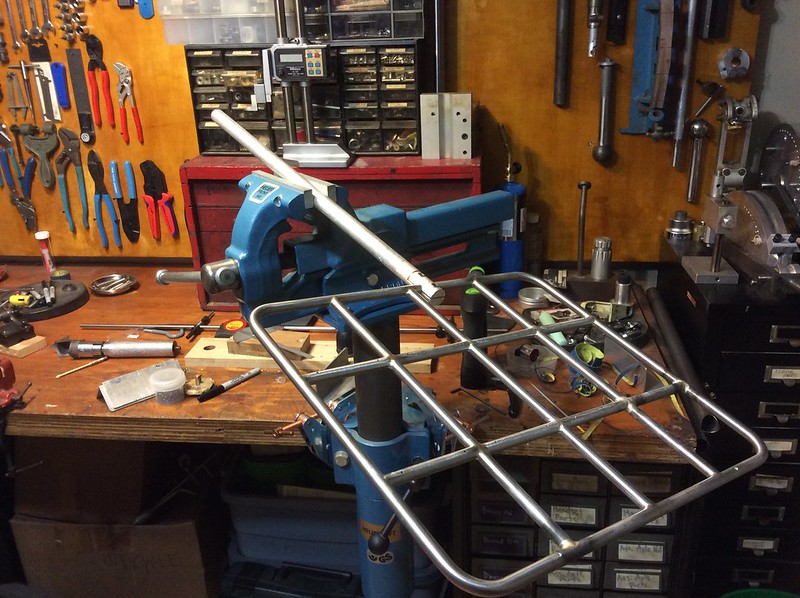

Although I've made a few forks to date, they have all been straight blade jobbies, largely because I haven't had access to a fork blade bender. There are no locally made commercial units, so it seemed I was going to have to make one myself. So behold my hillbilly-fabulous bender.

The mandrel is an offcut from a length of redgum fencepost I found in the woodshed. I cut, sanded and planed it to a constant radius and then routed a groove down the middle. For those of you not familiar with it, redgum is a fantastically dense and hard eucalypt which proved to be just about idea for this.

The fork tip clamp was knocked up out of some steel offcuts in the scraps bin, and is anchored by a pair of M10 cap screws that are threaded into hexagonal threaded rod couplers. The wood block is grooved to match the fork tip. Note the pint-sized bottle of Little Creatures - perhaps the finest beer in my world.

At the other end of the lump of wood is the bending stop. This is another M10 bolt and rod coupler, and provides a repeatable way of raking fork blades to exactly the same point.

Doing the actual bending itself is this little doohickey. It's a short length of 25mm angle, with a bored out 1/2" nut brazed to it. The nut pivots on a 1/2" bolt that pierces the bending arm. It all looks kinda Soviet era agricultural, but damn me the thing works. Effortless, repeatable and consistent bends. Total cost was about $10 spent at the bolt shop. Everything else was already in the parts bin or was scrounged for free. I'm pretty happy with the results.

Likes:

Likes:

Reply With Quote

Reply With Quote

Bookmarks