Thanks for the kind words Tom. As per pulse or manual beads: It depends where I am on the frame and how much power I need. I'd say most of the time I am pulsing with specific amperage settings, peak and background. Most times I manually weld is some spots on the bottom bracket and towards the inside of the frame where the seat / chain stays connect with Paragon's hooded dropouts (it gets quite thick here). But most times it's all pulse. I find I can regulate my heat control and timing a bit better this way? Since welding Titanium, all my pulse settings actually changed in steel as a result of that learning process. I have a lot more control and power now I think.

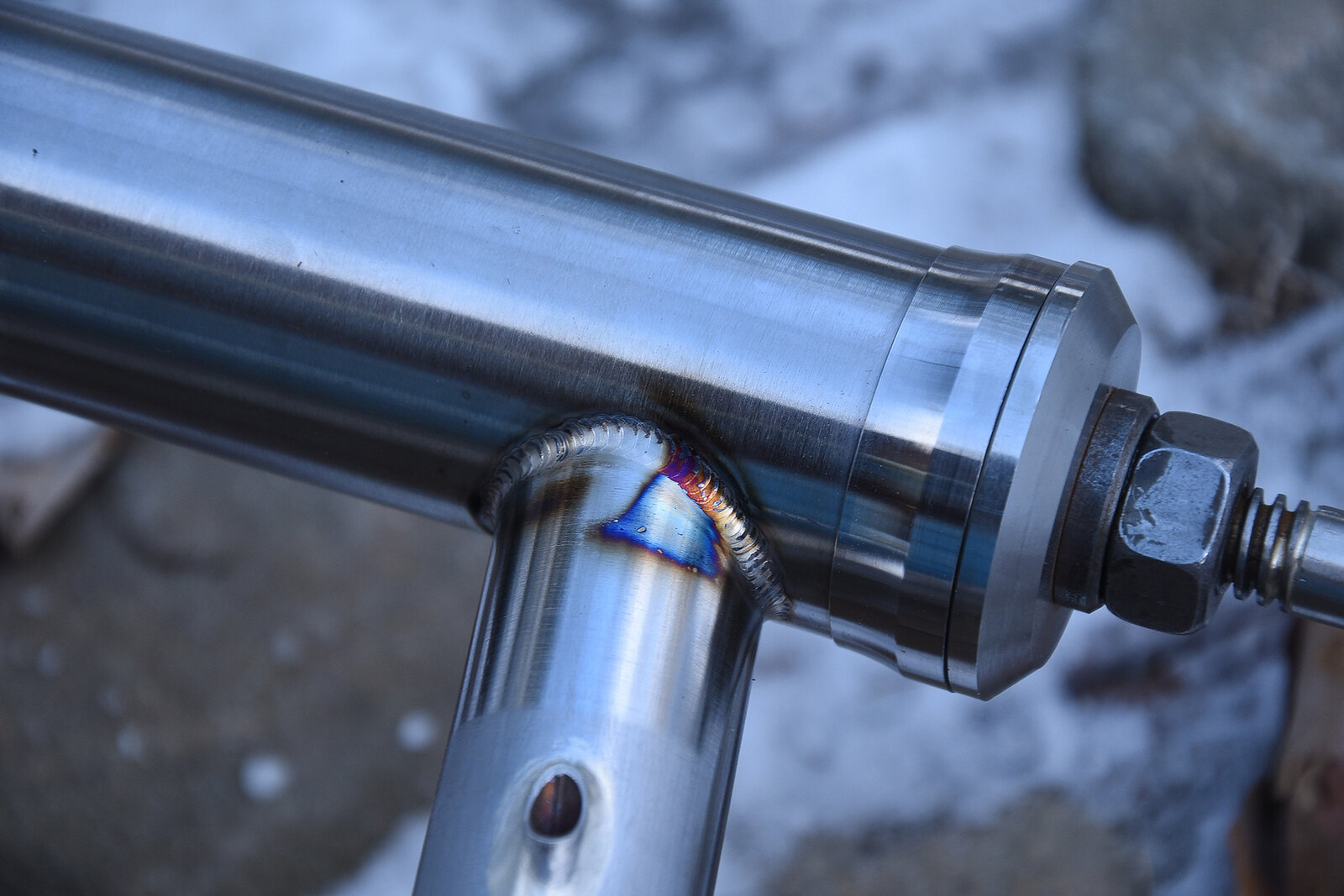

Here's a shot from today's effort:

To give you an idea, settings here are:

120 AMPS

25% Peak

9% Background

5 SCFH Purge

15-20 SCFH at the Torch

15 Second Post Flow

Pre-Flow is something like 2-5 seconds

No. 10 Alumina Nozzle with 1/16 Lanthanated Tungsten and matching gas lens

.035" Weldmold 880T Filler all day every day

Likes:

Likes:

Reply With Quote

Reply With Quote

Bookmarks