Originally Posted by

duggyballs

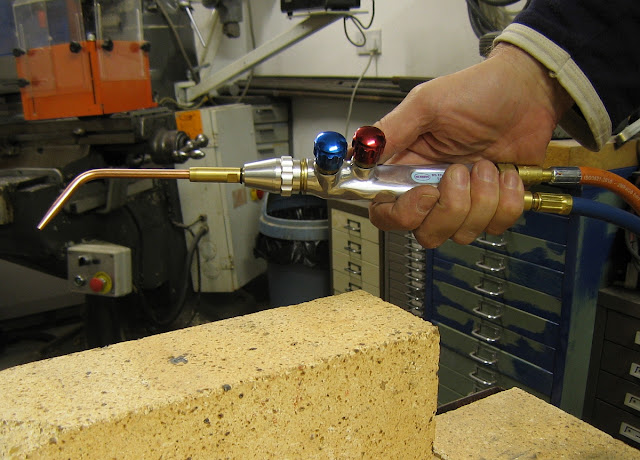

Hi guys, first time poster here, long time lurker. I'm a Mechanical fitter turner with some oxy/acetylene welding, brazing experience and 1 frame under my belt (Part lugged, part fillet brazed). I'm investing in some equipment as I'm in the States on holidays. Using equipment setup by someone else is one thing but buying it and deciding on the setup yourself is quite another. I live in Poland and I've just bought a Victor J-28, along with various tips - Uniweld 17-2 & 3 and some Gentec TEN stuff (elbow and tips) and "A" type torch end flashback arrestors. My plan is to have a Polish tanks and regulators, connected to 6mm tubing with the Western Enterprises adapters mentioned above, connected to a American hose (TM Tech or other) with flashback arrestors at the torch end. I havent included check valves at the moment as I don't know where to include them. I may have been rash buying the torch end arrestors already.

So, are check valves really necessary and if so, where would I connect them in my setup? I don't want to make the rig too fussy with adapters all over the place.

Should I abandon the torch end arrestors and get Polish arrestors at the regulators and get US check valves at the torch instead? Or arrestors to connect the two hoses and check valves at the torch? Any input would be greatly appreciated! I'm not sure if this thread is still active but Doug, any more input into your Ukrainian setup could be useful to me, as I have a feeling they share the same connections. Safety is obviously number one. I'm guessing a flame getting back to the tanks would be pretty much game over but how bad would an explosion in the hose be?

Likes:

Likes:

Reply With Quote

Reply With Quote

)

) ).

).

Bookmarks