Originally Posted by

Boedie

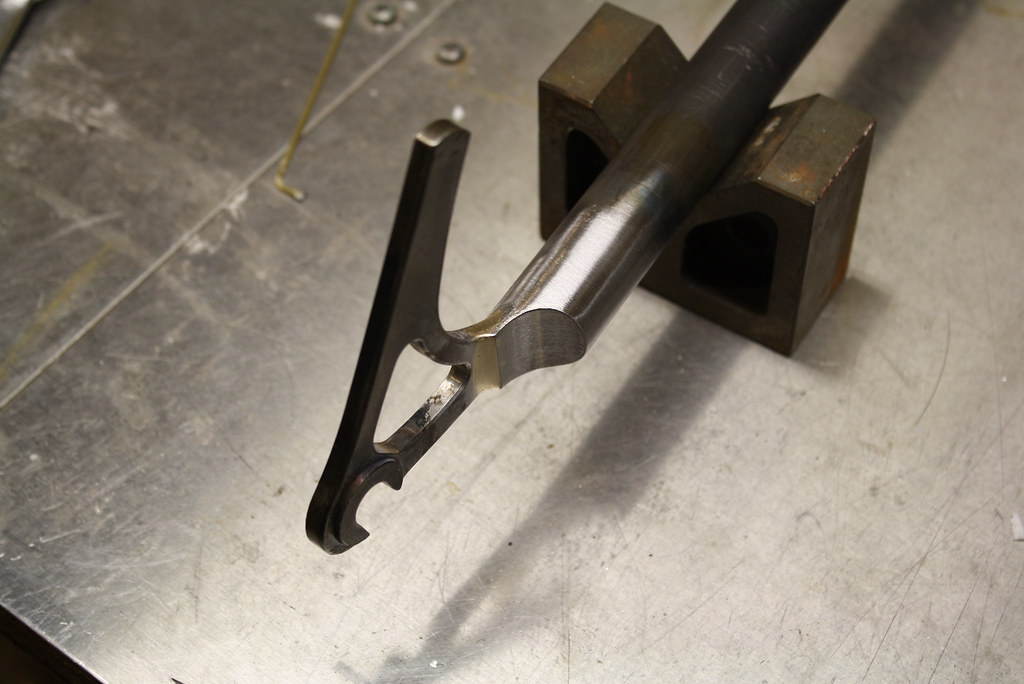

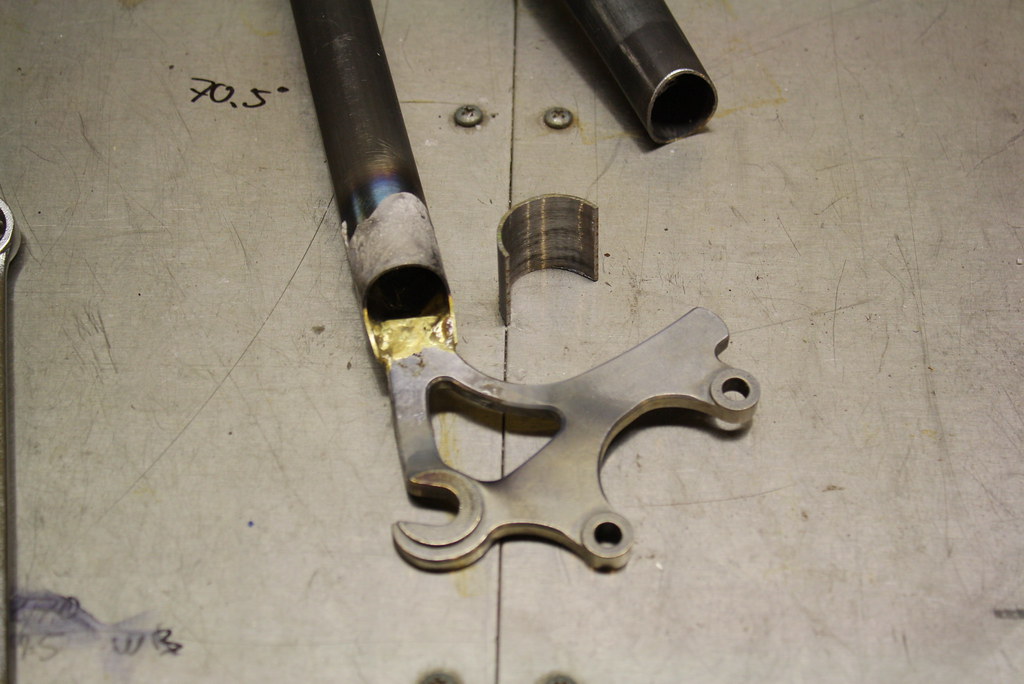

Hi, the example you have pictured is a TIG welded dropout, which is a little different than what I think you mean. I could be misinterperting your question. If you want to braze a dropout onto a chainstay, notch your chainstay the width of the dropout making sure to get the right orientation with your chainstay angle and getting the dropout vertical. Notch the tab on your dropout a hair (5-7mm), apply(file) your favorite treatment to the chainstay end, then clean (can't stress this enough) and flux and braze into place. I like to do both dropouts at the same time with either your fixture or a dummy axle keeping the dropouts in sink. You want to first tack the tangs/points into place, then simply fill up the chainstay with brass or silver, whichever you are using. If you focus most of the heat on the dropout itself, the brass will just slide right on down. Try and get as much filler as you can into the chainstay-ie, a rod of brass. There are a million pictures of different builders performing this, so a trip to Flickr will probably answer alot of questions for you. Practice brazing on a 1/4" plate, instead of a dropout into the chainstay. This will help you understand heat control and how to move the filler. Good luck.

Likes:

Likes:

Reply With Quote

Reply With Quote

Bookmarks